- Hygiene

- Sterilization

- Instrument sterilization basket

- NGS Engineering

- Products

- Catalogs

- News & Trends

- Exhibitions

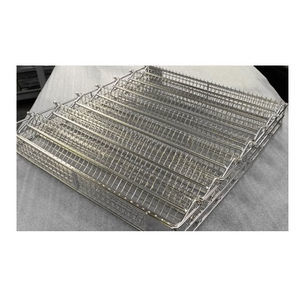

Instrument sterilization basket perforatedstainless steelautoclavable

Add to favorites

Compare this product

Characteristics

- Applications

- for instruments

- Other characteristics

- autoclavable, stainless steel, perforated

Description

Dipping baskets and carriers are used to hold or contain various products in cleaning and coating processes. These products include orthopedic implants, surgical instruments and ocular lenses. These baskets are often used used in autoclaves for the sterilization of products and/or medical or pharmaceutical equipment.

NGS have designed and manufactured many baskets and associated carriers for clients who manufacture these medical products. We understand of the constraints and strict requirements applied when these products are being coated or cleaned.

We can manufacture these baskets in various grades of stainless-steel type materials with options of finish such as electropolishing, acid resistant coatings or powder paint enamel.

Ultrasonic cleaning is used in the Pharma and healthcare industry for deep cleaning of instruments or products and removal of contamination. The Dipping baskets are designed around the following constraints:

The product to be cleaned or coated and

The cleaning or coating equipment.

In particular, the distance between the basket and the transducers in an ultrasonic bath may be important in addition to the location of the product or products that are in being cleaned as well as the sometimes-complex design of the automation equipment.

As an example, the image shows knee joints that are positioned in the baskets/jigs for ultrasonic cleaning after polishing. This basket of product is loaded into a carrier on a conveyor and is then automatically moved through the cleaning stations of the line and unloaded for packaging at the end.

Related Searches

- Sterilization basket

- Instrument sterilization basket

- Stainless steel sterilization basket

- Perforated sterilization basket

- Sterilization tray

- Instrument sterilization tray

- Endoscope sterilization basket

- Stainless steel sterilization tray

- Perforated sterilization tray

- Autoclavable sterilization tray

- Ophthalmic instrument sterilization basket

- Dental instrument sterilization basket

- ENT instrument sterilization basket

- Surgical instrument sterilization basket

- Surgical instrument sterilization tray

- Orthopedic instrument sterilization basket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.