- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Optical inspection system OptiSure™automated

Add to favorites

Compare this product

Characteristics

- Type

- optical

- Operational mode

- automated

Description

Provides optical assurance of fluid deposit dimensions and deposit placement to determine if dispense requirements have been met.

Overview

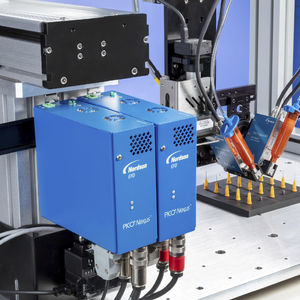

Using the automated dispensing system’s existing camera, Nordson EFD’s OptiSure AOI software inspects fluid deposit widths and diameters to determine if dispense requirements have been met and fluid placement is accurate.

It improves deposit accuracy and process control using closed-loop feedback, providing automated quality control data that will save manufacturers time and cost. The ability to integrate with DispenseMotion™ software also simplifies setup and programming for users.

Verify Deposit Accuracy

The OptiSure confocal laser verifies deposit height to determine dimensional accuracy of the deposit. It detects deposit measurements regardless of the transparency of the fluid or reflectivity of the deposit substrate, which can sometimes distort quality data.

When paired with the OptiSure confocal laser, the AOI software measures the height of a fluid deposit in addition to the width or diameter, providing 3D deposit verification. Instant quality feedback is obtained from the software and eliminates the need to purchase additional quality control equipment.

Features

Instant quality feedback

Precise 2D (width/diameter) verification with vision and 3D (height) verification with confocal laser

Constant closed-loop feedback

Automated optical inspection

Catalogs

Nordson EFD 10th Edition

148 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.