- Products

- Sterilization valve

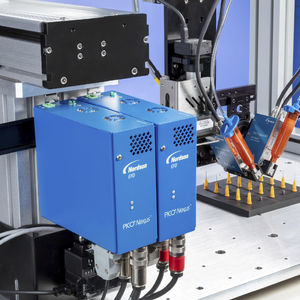

- Nordson Efd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Sterilization valve 754VCIPSIPstainless steel

Add to favorites

Compare this product

Characteristics

- Applications

- sterilization

- Function

- CIP, SIP

- Material

- stainless steel, PTFE

- Other characteristics

- aseptic

Description

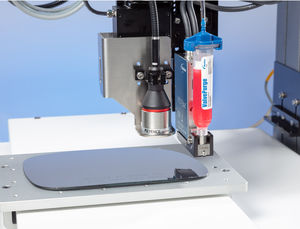

Nordson EFD's 754V aseptic dispense valve features a smooth fluid flow path that is free of any entrapment areas. FDA-compliant wetted parts make the valve suitable for CIP (Clean-In-Place) and SIP (Sterilize-In-Place) medical assembly processes.

With a flow path free of entrapment areas, the 754V provides fast, reliable operation. This fosters faster cycle and batch speeds, while electro-polished valve fluid bodies increase durability and corrosion resistance.

Flow volumes range from 0.5 microliter deposits to a continuous flow rate of 14.0 milliliters per second. The valve closes clean at the end of each cycle, with a fast cutoff that eliminates drips. Internal threads have been removed to facilitate easy cleaning.

Aseptic valve wetted parts are made of 316L stainless steel and PTFE, making them suitable for CIP (Clean-In-Place) and SIP (Sterilize-In-Place) processes. This compact diaphragm valve is ideal for aseptic and sterile fluid applications.

Features

FDA-compliant wetted parts

Accurate, consistent shot size

Clean cutoff eliminates drips

Diaphragm life exceeds 1x10⁸

Positive shutoff, no seals

Compact size and weight

Exceeds 500 cycles per minute

Compatible Fluids

Saline solutions

Optical monomers

Pill coating

Solvents

Vial filling

Food processing

Catalogs

Nordson EFD 10th Edition

148 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.