- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Pharmacy automated dispensing system RV Seriescompactwith computerrobotic

Add to favorites

Compare this product

Characteristics

- Applications

- pharmacy

- Other characteristics

- compact, with computer, robotic

Description

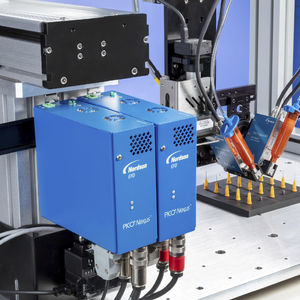

The RV Series automated fluid dispensing system features proprietary DispenseMotion™ software and a fully integrated CCD smart vision camera for best-in-class fluid placement accuracy and control at any angle along the 360° rotational plane.

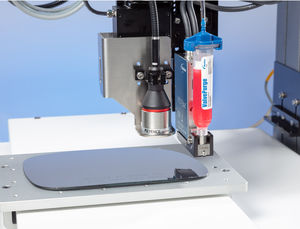

Specialized vision-guided dispensing software and an integrated CCD camera make the RV quick to set up and easy to program. True three-dimensional motion control provides easy programming of dots, lines, circles, arcs, compound arcs, and patterns on different planes.

The RV Series is a tabletop or desktop robot that also features single point needle adjustment and best-in-class dispense repeatability at +/- 8 μm. Platforms range from 300 x 300 mm to 620 x 500 mm, making them an ideal solution for batching or critical industrial dispensing applications.

Verify fluid deposit placement and accuracy with the OptiSure™ automated optical inspection (AOI) software. When paired with the OptiSure confocal laser, the AOI system measures the height of fluid deposits in addition to width and diameter, providing 3D dispense verification.

Features

On-screen preview of the dispensing path facilitates programming

Software wizard simplifies dispense tip-to-camera and dispense tip-to-workpiece offsets

Dispense tip alignment capability

Easy USB file upload and download

360° rotation for ID and OD dispensing

Benefits

Market-leading dimensional positioning accuracy and deposit placement repeatability

Faster cycle and batch times

Easier to setup and program quickly

Seamless integration into any manufacturing operation

Reduced production, material, and ownership costs

Catalogs

Nordson EFD 10th Edition

148 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.