- Dental

- Dental practice

- Medical compressor

- NUOVA A.S.A.V.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

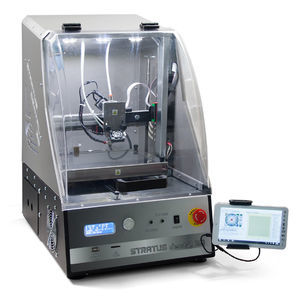

Medical compressor CSB24laboratorydentalpiston

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- dental, medical, laboratory

- Technology

- piston

- Number of dental workstations

- 1-workstation

- Options and accessories

- oil-free, with air dryer

- Pressure

8 bar

(116.03 psi)- Flow

260 l/min

(68.68 us gal/min)- Power

1.5 kW

(2.04 hp)- Weight

43 kg

(94.8 lb)- Noise level

Max.: 62 dB

Min.: 58 dB

- Length

440 mm

(17.3 in)- Height

532 mm

(20.9 in)

Description

High quality dry compressor for the production of compressed air, oil free

driven by 1 twin-cylinder engine to provide discrete volumes of air.

25 Lt tank

It can be equipped with a dryer like the larger models.

Appliance compliant with CE and ISO 8573-1 Class 0 certification

Suitable for 1 unit

ENG

Notes on drying compressed air

Quality air solutions help prevent corrosion, leaks, pollution and rust.

For the longest life and efficiency of your equipment, there are a number of solutions on the market to transform compressed air from where it is generated to where it is used into high quality air. Thanks to a range of products that extends from dryers to filters, compressed air is subjected to a treatment to reduce humidity and contaminants to achieve higher efficiency and air quality. Thus avoiding potentially costly production interruptions and a reduction in the efficiency and duration of the equipment used. Quality air solutions therefore represent a highly recommended investment evaluated both on a purely economic and sanitary level.

ENG

Absorption dryers

Absorption dryers use an absorption material called “desiccant” in order to absorb and remove moisture from the compressed air. The most commonly used desiccant material is composed of grains of hygroscopic salts or alumina. With this method, a PDP <3 ° C can be achieved. (down to -40 ° C or -70 ° C). An adsorption dryer is also advisable when the ambient temperature goes below the freezing point of the water, in order to avoid the formation of ice in the pipes and components. Adsorption dryers are typically used in the chemical, food and pharmaceutical industries and where a PDP <3 ° C is required.

Catalogs

No catalogs are available for this product.

See all of NUOVA A.S.A.V.‘s catalogsRelated Searches

- Oil-free air compressor

- Medical air compressor

- Dental air compressor

- Dry vacuum pump

- 1-workstation air compressor

- Piston air compressor

- Air compressor with air dryer

- Laboratory air compressor

- Dental vacuum pump

- Automatic disinfection system

- Fog disinfection system

- Air compressor on casters

- 2-workstation air compressor

- Screw air compressor

- Dental hygiene disinfection system

- Air compressor with soundproof housing

- 3-workstation air compressor

- Dental unit disinfection system

- UV curing unit

- Dental laboratory air compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.