Optical inspection system INSPECTPROOF™automatedbottlecompact

Add to favorites

Compare this product

Characteristics

- Type

- optical

- Operational mode

- automated

- Applications

- bottle

- Other characteristics

- compact, stand-alone

Description

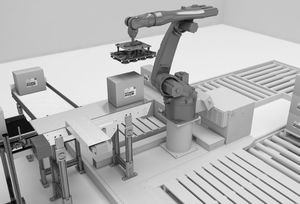

OPTEL’s InspectProof is an innovative and flexible automated vision system that provides extensive inspection of labels, cartons, trays, devices and cases. It quickly and reliably verifies product information such as lot and expiration date, cap and tamper-evident seals, label printing, component orientation and presence, sidesert and topsert. The automated vision system increases your overall line accuracy and quality assurance to avoid recalls. Our high-performance InspectProof reduces downtime, false rejects and rework, thereby increasing the efficiency of your lines.

We’ve combined our advanced software and optical technology to create an industry-leading OCV/OCR tool for printed and embossed codes, lot numbers, expiration dates, label ID numbers and DIN/NDCs, ensuring that the printed information is accurate every time.

KEY BENEFITS

Up to 2,000 ppm

100% on-line inspection

Quick and easy steps with unlimited recipe storage

Configurable alarms

Fully integrated product tracking

Data management tools – Connectivity with ERP/SCADA system, batch record and device control

High accuracy (low false-reject rate)

IO control – Stand-alone units (PLC integration not required)

No contact with product

Toolless changeovers for quick and simple software setup

Compact design

Characters (OCV/OCR on lot, expiration date, DIN/NDC, label ID and serial number)

Grading of linear barcodes and 2D codes (Data Matrix) according to ISO/IEC standards

GMP design

Embossed codes

Print positioning and quality

Presence and positioning of bottle caps

Tamper-evident seals

Label presence and orientation

Presence of inserts, topserts, sideserts

Product measurements

Product conformity

Catalogs

No catalogs are available for this product.

See all of Optel Vision‘s catalogsRelated Searches

- Packaging system for the pharmaceutical industry

- Automatic packaging machine

- Floor-standing packaging machine

- Inspection system for the pharmaceutical industry

- Medicine packaging system

- Automated inspection system

- Box packaging machine

- Semi-automatic packaging machine

- Optical inspection system

- Case packaging machine

- Production packaging machine

- Compact inspection system

- Bottle packaging machine

- Manual packaging machine

- Bottle inspection system

- Vial inspection system

- Capsule inspection system

- Continuous inspection system

- Tablet inspection system

- Manual inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.