Fully-automatic packaging machine PACKSTATION™ CAPcasefor boxesbottle

Add to favorites

Compare this product

Characteristics

- Operational mode

- fully-automatic

- Container type

- case, for boxes, bottle

- Application domain

- for the pharmaceutical industry

Description

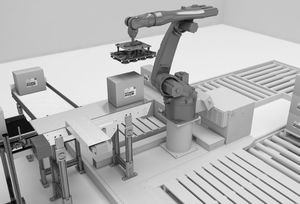

OPTEL’s PackStation™ CAP is an aggregation solution that identifies which items are packed together in which cases, building the parent/children relationship between different packages. With our extended retrofit experience on various kinds of case packers, OPTEL’s PackStation™ CAP can be installed in any case packer, while maintaining your machines’ highest efficiency. With our unique TrackSafe™ Data Matrix reading technology, you get the most efficient reading, ensuring maximum performance of packing operations.

Can be installed in any case packer

Aggregation with no impact on case packer maximum throughput

EPC 2D, EPC 1D and barcode inspections on case label, including grading

Designed to match case packer format ranges

Toolless changeovers

User-friendly interface

Compliant with worldwide regulations

An image of the codes printed on products is inspected and verified by comparing it to a reference image. The result of the inspection is submitted.

A serialized case label is printed and applied when the children verification is successful.

The label is inspected by comparing it to a reference image once the case reaches the appropriate sensor. The result of the inspection is communicated to the OEM, which accepts or rejects the items. If the inspection is successful, the items are associated (aggregated).

If the case is deemed defective, it is ejected either by OPTEL (Option OPT) or the OEM (Option OEM).

Catalogs

No catalogs are available for this product.

See all of Optel Vision‘s catalogsRelated Searches

- Packaging system for the pharmaceutical industry

- Automatic packaging machine

- Floor-standing packaging machine

- Medicine packaging system

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Box packaging machine

- Semi-automatic packaging machine

- Optical inspection system

- Case packaging machine

- Production packaging machine

- Bottle packaging machine

- Compact inspection system

- Manual packaging machine

- Bottle inspection system

- Capsule inspection system

- Continuous inspection system

- Tablet inspection system

- Manual inspection system

- Stand-alone inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.