- Secondary care

- Orthopedic surgery

- Metallic compression plate

- Ortho Baltic Implants

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

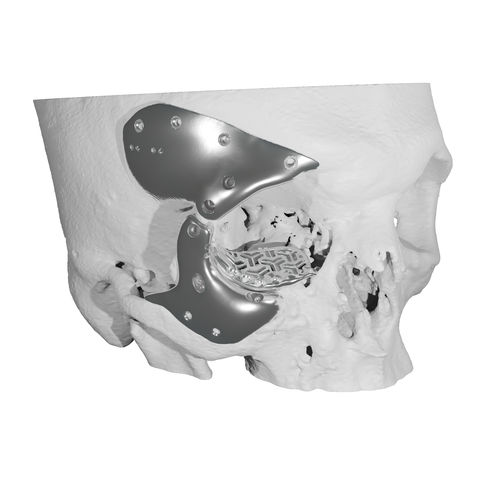

Maxillofacial compression plate Custom-made implantmetallic

Add to favorites

Compare this product

Characteristics

- Applications

- maxillofacial

- Materials

- metallic

Description

In clinical practice for maxillofacial reconstruction, bone grafts, bone cement and standard implants (meshes, plates and screws, augments) used are traditionally shaped manually (bent and cut), either preoperatively or intraoperatively. However, with these materials, it is difficult to restore the aesthetic of the face and evenly fill the defects, which may lead to irregular healing of the bone and unsatisfying aesthetic results. Patient-specific maxillofacial reconstructive implants solve these problems. Therefore, in case of large maxillofacial defects and in order to restore the patient’s aesthetic and decrease the risk of infections and other complications, it is recommended to use patient-specific maxillofacial reconstruction implants that are manufactured individually for each patient with regard to the patient’s anatomy, pathology and the requirements for the design of the implant defined by the surgeon.

Patient-specific maxillofacial reconstruction implants are manufactured individually for each patient with regard to the patient’s anatomy, pathology and the requirements of the treating surgeon for the design, fixation solutions and materials used. They are designed on a personalized maxillofacial anatomical model that is recreated from computer tomography scan images. Therefore, a patient-specific implant suits the patient’s anatomy perfectly and evenly fills the defects thus aesthetically restoring the maxillofacial morphology and symmetry, and occlusion (if applicable), and using patient-specific surgical guides ensures accuracy of implant positioning and insertion.

Catalogs

No catalogs are available for this product.

See all of Ortho Baltic Implants‘s catalogsOther Ortho Baltic Implants products

Patient-specific Medical Devices

Related Searches

- Bone plate

- Compression plate

- Metallic compression plate

- Acetabular prosthesis

- Revision acetabular prosthesis

- Cemented acetabular prosthesis

- Cranial implant

- Custom-made cranial implant

- Periorbital implant

- Resection guide

- Custom-made periorbital implant

- Custom-made temporomandibular implant

- Hip prosthesis resection guide

- Temporomandibular implant

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.