- Products

- Production system

- Oxford Instruments

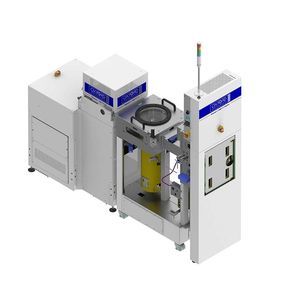

Production system PlasmaPro 800 RIE

Add to favorites

Compare this product

Description

The PlasmaPro 800 offers a flexible solution for reactive ion etching (RIE) processes on large wafer batches and 300mm wafers, in a compact footprint, open-loading system. The large wafer platen allows for production scale batch processing and 300mm wafer handling.

High performance processes

Excellent substrate temperature control

Precise process control

Proven processes for 300mm single wafer Failure Analysis

Features

The PlasmaPro 800 with a 460mm diameter table offers full 300mm or large batch 43 x 50mm (2”) capacity, enabling full production solutions and establishing the PlasmaPro 800 as a well proven market leading product.

Allowing maximum process flexibility for compound semiconductor, optoelectronics, and photonics applications, the PlasmaPro 800 provides:

Large electrode - Low Cost of Ownership

Etch end point detection - Reliability and serviceability

Endpoint detection by laser interferometry and/or optical emission spectroscopy - Can be fitted to enhance etch control

Options of a 4-, 8- or 12-line gas pod - Provides flexibility in processes and process gases, and may be remotely sited in the service area, away from the main process tool

Close-coupled turbo pump - High pumping speed and excellent base pressure

Datalogging - Traceability and history of chamber and process conditions

Fluid-cooled and/or electrically-heated electrodes - Excellent electrode temperature control and stability

Applications

Failure analysis dry etch de-processing using our specially configured failure analysis tools, with RIE and dual-mode

RIE/PE processes ranging from packaged chip and die etch through to full 300mm wafer etch

Catalogs

No catalogs are available for this product.

See all of Oxford Instruments‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.