- Products

- Production system

- Oxford Instruments

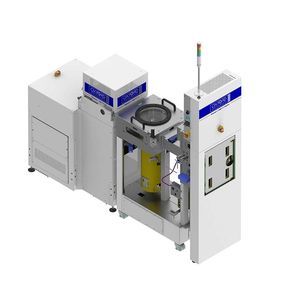

Production system PlasmaPro 100 ALE

Add to favorites

Compare this product

Description

The PlasmaPro 100 ALE delivers precise process control of etching for next-generation semiconductor devices. Specially designed for processes such as recess etching for GaN HEMT applications and nanoscale layer etching, the system's digital/cyclical etch process offers low damage, smooth surfaces.

Digital/Cyclical etch process – etching equivalent of ALD

Low damage

Smooth etch surface

Superb etch depth control

Ideal for nanoscale layer etching (e.g. 2D Materials)

Wide range of processes and applications

Features

As layers become thinner to enable the next-generation semiconductor devices, there is a need for ever more precise process control to create and manipulate these layers. The PlasmaPro 100 ALE delivers this by enhancing our Cobra ICP platform with specialised hardware for atomic layer etching.

Delivers reactive species to the substrate, with a uniform high conductance path through the chamber - Allows a high gas flow to be used while maintaining low pressure

Variable height electrode - Utilises the 3-dimensional characteristics of the plasma and accommodate substrates up to 10mm thick at optimum height

Wide temperature range electrode (-150°C to +400°C) which can be cooled by liquid nitrogen, a fluid re-circulating chiller or resistively heated - An optional blow out and fluid exchange unit can automate the process of switching modes

A fluid controlled electrode fed by a re-circulating chiller unit - Excellent substrate temperature control

RF powered showerhead with optimised gas delivery - Provides uniform plasma processing with LF/RF switching allowing precise control of film stress

High pumping capacity - Gives wide process pressure window

Catalogs

No catalogs are available for this product.

See all of Oxford Instruments‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.