- Products

- Production system

- Oxford Instruments

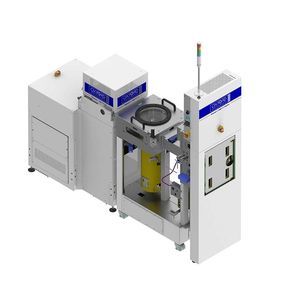

Production system PlasmaPro 100 Estrelas

Add to favorites

Compare this product

Description

The PlasmaPro 100 Estrelas platform is designed to give total flexibility for Deep Reactive Ion Etching (DRIE) applications - serving a diverse set of process requirements across the Micro Electromechanical Systems (MEMS), Advanced Packaging and Nanotechnology markets. Developed for research and volume production, the PlasmaPro 100 Estrelas offers the ultimate flexibility with Bosch and Cryogenic processes.

High etch rate and high selectivity with Bosch process

Smooth sidewall & high aspect ratio processes

Highly anisotropic (vertical) profile

Low rate, low power for nano-silicon etch and notch control (SOI)

Tapered via etches

Wide range of applications

Mechanical or electrostatic clamping (substrates’ compatibility)

Improved reproducibility

Increased mean time between cleans (MTBC)

Overview

DSiE technique or Deep Reactive Ion Etching (DRIE) combines isotropic silicon etching and passivation steps repeatedly to obtain anisotropic profiles. Using high density plasma source and fast gas-switching capability, this technique enables you to achieve profile verticality, smooth sidewalls and high etching rates with high selectivity to masking materials.

From smooth sidewall processes to high rate cavity etches and high aspect ratio processes to tapered via etches, the PlasmaPro 100 Estrelas has been designed to ensure that the wide range of applications in MEMS, advanced packaging and nanotechnology can be realised without the need to change chamber hardware.

Nano and microstructures can be realised as the hardware has been designed with the ability to run Bosch™ and Cryo etch technologies in the same chamber.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Oxford Instruments‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.