- Products

- Production system

- Oxford Instruments

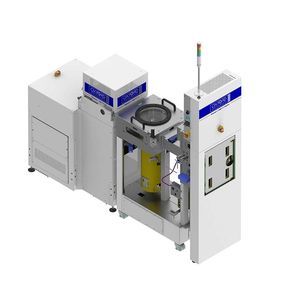

Production system PlasmaPro 100 Cobra

Add to favorites

Compare this product

fo_shop_gate_exact_title

Description

The PlasmaPro 100 Cobra ICP RIE system utilises a high-density inductively coupled plasma to achieve fast etch rates. The process modules offer excellent uniformity, high-throughput, high-precision and low-damage processes for wafer sizes up to 200mm, supporting a number of markets including, GaAs & InP laser optoelectronics, SiC & GaN power electronics/RF and MEMS & sensors.

High etch rate and high selectivity

Low damage etch and high repeatability processing

Single wafer load lock or clusterable with up to 5 process modules

He backside cooling for optimum temperature control

Wide temperature range electrode, -150°C to 400°C

Compatible with all wafer sizes up to 200mm

Rapid change between wafer sizes

In-situ chamber cleaning and end-pointing

Overview

The Cobra® ICP plasma source produces high-density reactive species at low pressure. Substrate DC bias is driven by a separate RF generator, allowing independent control of radicals and ions, according to process requirements.

Oxford Instruments’ PlasmaPro 100 process modules offer a 200mm platform with single wafer and multi-wafer batch capability. The process modules offer high throughput, high precision and excellent uniformity with clean smooth vertical profiles and etch surfaces. Our systems have a wide install base within high volume manufacturing (HVM), with well-developed process solutions.

Features

Delivers reactive species to the substrate, with a uniform high conductance path through the chamber - Allows a high gas flow to be used while maintaining low chamber pressure, which provides wide process windows for advanced application development

VIDEO

Catalogs

No catalogs are available for this product.

See all of Oxford Instruments‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.