- Laboratory

- Sample management

- Automatic sample preparation system

- Oyster Bay Pump Works

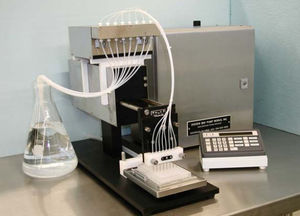

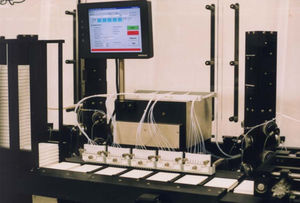

Automated sample processor M10-D1+2 floor-standingmicroplatestrip

Add to favorites

Compare this product

Characteristics

- Operation

- automated

- Configuration

- floor-standing

- Preparation format

- microplate, strip

Description

This microplate processing automation system integrates up to 10 functions in the sequence required by your processes. It provides liquid handling functions, product marking, and in-process inspection tools needed to produce your product. System speeds can range between 400 and 1200 plates per hour depending on configuration.

Typically offered functions are listed below and others can be requested

stack load

stack accumulators (shown at right)

static elimination

strip push down

plate orientation check

printing (frames/tabs)

vision inspect printing

color coding

particulate removal

aspiration

washing

blocking

drying

precision filling

bubble detection

fill verification

vision inspect fills

bar code reading

data acquisition

reject stacker

lid application

restacking

off ramp (or transfer)

Catalogs

No catalogs are available for this product.

See all of Oyster Bay Pump Works‘s catalogsOther Oyster Bay Pump Works products

Microplate Processing Automation

Related Searches

- Sample processor

- Automated sample preparation system

- Laboratory sample processor

- Floor-standing sample processor

- Washing sample processor

- Microplate sample processor

- Media dispenser

- Reagent dispenser

- Benchtop media dispenser

- Laboratory media dispenser

- Automated media dispenser

- Sample processor on casters

- Laboratory reagent dispenser

- Filling sample processor

- Benchtop reagent dispenser

- Strip sample processor

- Automated reagent dispenser

- Manual media dispenser

- Microplate media dispenser

- Floor-standing media dispenser

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.