- Laboratory

- Sample management

- Automatic sample preparation system

- Oyster Bay Pump Works

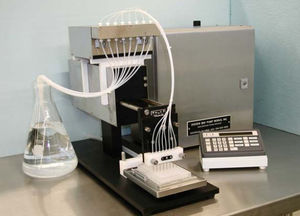

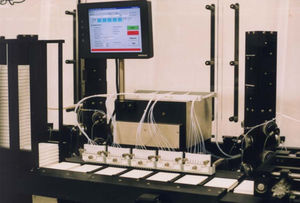

Automated sample processor M3-D serieswashingfillingon casters

Add to favorites

Compare this product

Characteristics

- Operation

- automated

- Preparation type

- washing, filling

- Configuration

- on casters

- Preparation format

- microplate

- Other characteristics

- ultrasonic

Description

This microplate processor provides automated integration of up to 3 process functions in series. Different

functions can be selected according to requirements. Three typical system configurations:

• M3-D1: with “Day 1” functions including precision filling, bubble detection, and ultrasonic fill verification

• M3-D2: with “Day 2” functions (3 manifold stations) including filling (washing or blocking) and aspiration

• M3-D1+2: with both “Day 1” and “Day 2” functions (2 manifold stations plus 1 precision fill station)

Manifold stations are interchangeable and can be swapped out and sequenced as needed for different process passes. There are manifolds for filling, aspirating, and combined filling and aspirating at one station (for multiple wash steps). Different nozzle sizes and arrays are available to accommodate different well geometries (flat, “C”, “U”, star, low volume, etc.) Manifolds are available for 96 well and 384 well plates (and can be made to order for

different well arrays).

The robust system design provides the precision and reliability needed to efficiently produce a quality product.

System speeds can range between 400 and 1200 plates per hour depending on configuration. Stacks for feeding and restacking have capacity for 30 plates. (Many more functions are available on our larger systems.)

Catalogs

No catalogs are available for this product.

See all of Oyster Bay Pump Works‘s catalogsOther Oyster Bay Pump Works products

Microplate Processing Automation

Related Searches

- Sample processor

- Automated sample preparation system

- Laboratory sample processor

- Floor-standing sample processor

- Washing sample processor

- Microplate sample processor

- Media dispenser

- Reagent dispenser

- Benchtop media dispenser

- Laboratory media dispenser

- Automated media dispenser

- Laboratory reagent dispenser

- Sample processor on casters

- Benchtop reagent dispenser

- Filling sample processor

- Strip sample processor

- Automated reagent dispenser

- Manual media dispenser

- Microplate media dispenser

- Microplate reagent dispenser

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.