- Laboratory

- Sample management

- Automatic reagent dispenser

- Oyster Bay Pump Works

Automated reagent dispenser laboratoryfor microplatesbenchtop

Add to favorites

Compare this product

Characteristics

- Operation

- automated

- Applications

- laboratory, for microplates

- Configuration

- benchtop

Description

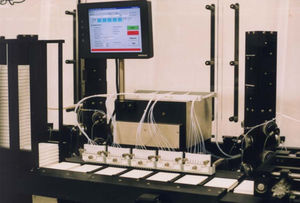

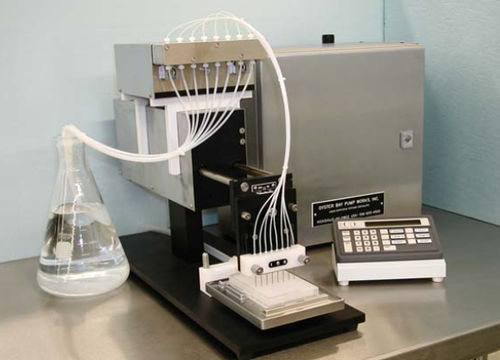

Each system has 4 component modules:

• nozzle indexing module

• pump module

• control interface

• control cabinet

The nozzle indexing module is the unit on which a plate is placed to be filled. It includes the automated mechanism to position the nozzles over the wells or priming tray. It is optionally available with an extra "nozzle shift" motion to enable filling 384 well plates with the same grouping of 8 nozzles used to fill 96 well plates.

The pump module contains a grouping of pumps with tubing and fill nozzles. Nozzles are attached to a holder that mounts onto the nozzle indexing module. For most solutions, dispense volume CV's of 1% or below can be expected down to 10 µl doses and 10% or below down to 1 µl doses. Various pump module designs are available to suit different fill pattern and volume range requirements. They are designed for quick changeover

allowing for multiple uses of the same basic system. Pumps can be arranged to fill all wells with the same reagent or to put different reagents into specific wells. System speed depends on how many pumps are used

The control interface can be your choice of:

• manual keypad interface module (most commonly used)

• manual PC interface (via RS232 com cable to PC serial port) (requires optional software and PC)

• automated remote PC interface (via RS232 com cable to PC serial port) (requires optional software)

Catalogs

No catalogs are available for this product.

See all of Oyster Bay Pump Works‘s catalogsOther Oyster Bay Pump Works products

Microplate Processing Automation

Related Searches

- Sample processor

- Automated sample preparation system

- Laboratory sample processor

- Floor-standing sample processor

- Washing sample processor

- Microplate sample processor

- Media dispenser

- Reagent dispenser

- Benchtop media dispenser

- Laboratory media dispenser

- Automated media dispenser

- Laboratory reagent dispenser

- Sample processor on casters

- Benchtop reagent dispenser

- Filling sample processor

- Strip sample processor

- Automated reagent dispenser

- Manual media dispenser

- Microplate media dispenser

- Microplate reagent dispenser

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.