Inkjet printer JET3up EPfor plasticsfor paperautomatic

Add to favorites

Compare this product

Characteristics

- Printing technology

- inkjet

- Printing media

- for paper, for plastics

- Other characteristics

- automatic

Description

The advanced printer designed specifically for egg production

JET3up EP fits into your egg production environment as neatly as eggs in their carton. It gives you all the functionality and power of the JET3up, but with features designed specifically for the coding of eggs and egg cartons. It integrates easily with MOBA and Diamond sorting machines, with each printer marking 30,000 eggs every hour. In an 8-lane operation with 8 printers, this means up to 252,000 eggs every hour.

Red, blue and green inks give superb legibility on white and brown shells alike, and you can place the code wherever you want on the egg itself, via a print head that can fit in the tightest of spaces. With 800 user-friendly functions and options to choose from, this is the ultimate continuous inkjet solution for egg producers.

JET3up EP at a glance

Coding and marking of eggs and egg cartons

Integrates easily with MOBA and Diamond egg sorting machines

Prints 30,000 eggs per hour

Flexible positioning of code

Sealtronic print head technology rids clogging and frequent head cleaning

High efficiency to help control operating costs

Multiple egg shell inks, fonts and languages available

IP65 PRO version available

Ideal for egg producers

Sealtronic

LEIBINGER's world-famous automatic nozzle sealing technology

LEIBINGER's renowned automatic nozzle sealing technology, Sealtronic, ensures consistently high-quality printing without the need for cleaning procedures and ensures maximum printer availability.

VIDEO

Related Searches

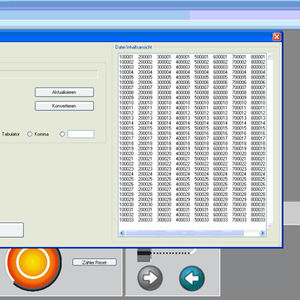

- Viewer software

- Control software

- Windows software

- Scheduling software

- Monitoring software

- Online software

- Printing software

- Medical printer

- Multipurpose printer

- Paper printer

- Inkjet printer

- Automatic printer

- Facial software

- Centralized software

- Plastic printer

- Glass printer

- Printer with touch screen

- Economical printer

- Packaging film printer

- Textile printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.