- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

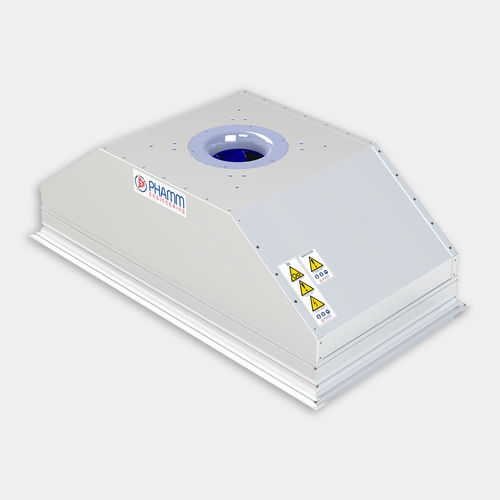

Cleanroom laminar flow module FFUceilingvertical

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for cleanrooms

- Configuration

- ceiling

- Direction of flow

- vertical

Description

Phamm Engineering's great production flexibility makes it possible to create non-standard models according to customer specifications.

reliability

Each FFU works independently, the failure of one or more units does not compromise the integrity of the entire system.

modularity

The modularity of our products allows for rapid expansion, reorganization and relocation of the same. You can rearrange the zones simply by changing their location. Units can be swapped with light panels or in empty panels.

The ceiling will be made using extruded and powder-coated aluminum profiles, infilled, for the positions not occupied by the lamps and filters, with RAL 9010 sheet metal or laminate panels.

The entire perimeter of the structure includes a closure made of plastic material, in order to create an isolating wall with the rest of the room. These straps, made of soft antistatic PVC material, allow for simple passage of both operators and materials. The straps will reach a height of between 15 and 20 mm from the ground.

ENERGY EFFICIENCY

The control system carries out the exact detection of the parameters involved in the system during all phases of use. The controls ensure that energy consumption is minimized and that usage performance is always the best.

Flexibility

It is possible, by increasing the modules and inserting them into existing systems, to increase the class of the installation area.

Catalogs

Cleanroom Softwall

12 Pages

VARIOUS PRODUCTS

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.