- Laboratory

- Sample management

- Powder Systems Limited (PSL)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Basket filter drier GFD® for liquidsfor solidslaboratory

Add to favorites

Compare this product

Characteristics

- Filter type

- basket

- Fluid

- for liquids, for solids

- Applications

- laboratory, for the pharmaceutical industry, separation

- Material

- stainless steel

- Other characteristics

- compact, pressure, Nutsche

Description

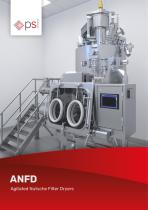

The GFD®Pilot is an Agitated Nutsche Filter Dryer (ANFD) that carries out solid-liquid separation processes at kilolab and pilot scale. It facilitates feasibility and proof of concept activities developed during smaller scale research and development stages. In spite of being a smaller, compact filter dryer, it provides the quality, reliability and efficiency of the full size PSL ANFD filter dryers.

PSL’s unique GFD® technology was developed to overcome the well-known production challenges faced by manufacturers when using traditional production methods such as Büchner filtration and oven tray-drying.

It consists of an agitated vessel designed to work under vacuum and under pressure. The vessel can be made of Borosilicate 3.3 glass, 316L Stainless Steel or Alloy 22 and has a heated jacket for efficient drying. Solid-liquid separation is performed within the unique filtration basket, which can be removed to ease and maximise product recovery.

The GFD®Pilot technology is designed to be the logical scale-up ANFD from the GFD®Lab which is used in laboratory conditions. It assists in evaluation and development of the desired end product prior to scaling up to commercial production.

Features and Benefits

Combined Filtration and Drying

The GFD®Pilot is an all-in-one filter dryer designed for use at pilot plant production scale. It complies with Good Laboratory Practices (GLP) and is commonly used for pharmaceutical and fine chemical processing applications. Developers and manufacturers can complete a wide range of processes in a single, standardised system:

Slurry Filtration (solid-liquid separation)

Product Washing

Re-slurry

Product Sampling

Product Discharge

Catalogs

Other Powder Systems Limited (PSL) products

Nutsche Filter Dryer Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.