- Medical & Pharmaceutical industry

- Components for the medical industry

- Powder Systems Limited (PSL)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Basket filter drier for liquidsfor solidsfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Filter type

- basket

- Fluid

- for liquids, for solids

- Applications

- for the pharmaceutical industry, separation, for chemical applications, for pilot plants

- Material

- stainless steel

- Other characteristics

- vacuum, pressure, high-efficiency, high-performance, Nutsche, with agitation, for powders

Description

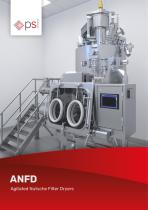

Everyday our technology is assisting hundreds of pilot and production facilities around the world to reliably manufacture and bring their products to the market faster. PSL Agitated Nutsche Filter Dryers (ANFD) are being used in a wide range of industries such as pharmaceuticals, fine chemicals and precious metals.

Our ANFD Filter Dryer production systems were developed to efficiently wash and isolate solids in the most complex chemical synthesis processes and challenging production environments. Our solutions are designed to overcome well-known challenges faced by manufacturers when using traditional production methods, such as Büchner filtration and oven tray-drying.

Each of our filter dryers consists of an agitated vessel designed to work under vacuum and under pressure. The vessel can be made of either stainless steel or alloy 22 and can be coated with specific materials such as PFA (perfluoroalkoxy alkane). It is also equipped with a heated jacket and heated agitator for efficient product drying and mixing.

Features and Benefits

Combined Filtration and Drying

PSL’s Agitated Nutsche Filter Dryers are an all-in-one piece of equipment designed to comply with Good Manufacturing Practices (GMP) for regulated development and production activities. They allow process developers and manufacturers to complete a wide range of processes into one single system

CGMP Compliance, Delivered

PSL’s strength lies in our comprehensive knowledge of the GMP regulations combined with our practical experience and knowledge of a wide range of manufacturing workflows

Catalogs

Other Powder Systems Limited (PSL) products

Nutsche Filter Dryer Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.