- Products

- Catalogs

- News & Trends

- Exhibitions

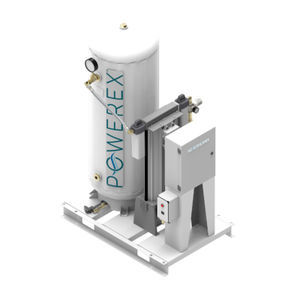

Medical air compression system MDRE0406screwrotarystationary

Add to favorites

Compare this product

Characteristics

- Applications

- medical

- Technology

- screw, rotary

- Configuration

- stationary

- Number of dental workstations

- 2-workstation, 3-workstation

- Options and accessories

- oil-free, with pump

- Power

Min.: 80 W

(0.11 hp)Max.: 300 W

(0.41 hp)- Weight

Min.: 2,480 lb

(1,124.9 kg)Max.: 3,910 lb

(1,773.5 kg)- Noise level

Min.: 71 dB

Max.: 81 dB

Description

Our Powerex medical rotary screw compressor series leverage an oil-free, risk free rotary screw design in a sound enclosure cabinet in order to minimize noise and system footprint. These medical packages are preferred by hospitals and laboratories worldwide.

Features

OIL-FREE RISK FREE ROTARY SCREW DESIGN

Long acknowledged to be the most efficient, low cost and reliable method for producing oil-free air, the rotary screw compressor is available in sizes ranging from 20-100 horsepower.

LOW INSTALLATION COST

Conveniently located utility connections provide quick and easy installation. Units are thoroughly factory tested prior to shipment. All models have the same compact footprint. Air or water cooled models are available.

QUIET

Full sound enclosure with easy to remove panels provide quick access for routine maintenance. Quiet operation 64-74 dB(A) is standard for both air and water cooled models.

PREMIUM EFFICIENT MOTOR

A premium efficient, EISA heavy-duty motor is flange mounted to the compressor for permanent trouble-free alignment.

SYSTEM OPTIONS

Air or Water cooled cooling system

CO Monitor (standard on Medical Systems, optional on Lab)

VFD control panel

Activated carbon final filters

AIR TREATMENT CENTER PACKAGE

Includes:

Dual heatless twin tower desiccant dryers, dual filters, dual regulators and dual safety relief valves

Dew point monitor

CO monitor (optional)

A sample port

Air receiver

All components mounted and plumbed together with bypass valves

Related Searches

- Oil-free air compressor

- Medical air compressor

- Medical gas outlet

- Manifold

- Medical gas manifold

- Vacuum system

- Medical vacuum system

- Anesthetic gas alert system

- DIN outlet

- Medical gas supply unit

- Medical gas medical alert system

- Automatic manifold

- Lubricated vacuum system

- Supply manifold

- Dry vacuum system

- Oxygen supply unit

- Rotary vane vacuum system

- Changeover manifold

- High-pressure manifold

- Wall-mounted medical gas supply unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.