- Laboratory

- Physico-chemical analysis

- Oxygen sensor

- PreSens Precision Sensing GmbH

Flow sensor NTH-PSt7oxygenlaboratory

Add to favorites

Compare this product

Characteristics

- Evaluation type

- flow, oxygen

- Applications

- laboratory

Description

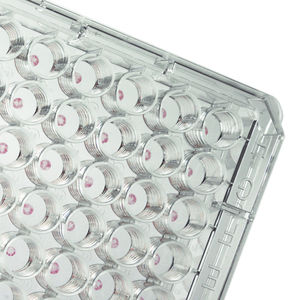

The glass fiber with its oxygen-sensitive tip (< 50 µm with tapered sensor tip TS, < 230 µm with flat-broken sensor tip TF) is protected inside a stainless steel needle and can be extended for measurements. As long as the sensor tip is retracted and sheltered inside this needle the microsensor can be pierced through septum rubber or any other harsh material. With its small tip size and fast response time (t90 < 3 s) this sensor is ideally suited for research and packaging applications, where micro-invasive and small sensors are needed.

High spatial resolution (down to < 50 μm)

High temporal resolution (t90 < 3 sec.)

No consumption of oxygen

Signal independent of flow velocity

Measures in liquids as well as in gas phase

APPLICATIONS

Tissue Engineering

Oxygen microsensors measure the oxygen content in various volume compartments of the tissue engineering constructs. To do so, hair-thin sensors are inserted into the constructs and the oxygen content is measured online. In this way, the oxygen partial pressure is measured with a high local resolution and correlated with the constructs tissue quality (composition of the extracellular matrix).

Packaging & Quality Control

Oxygen inside packaging can lead to oxidative deterioration of certain products. Therefore, determination of the oxygen content within packages or pharmaceutical vials is of essential importance to ensure both the filling quality and the long-term storage stability. With our micro-invasive needle-type oxygen microsensors we offer a simple tool to determine residual oxygen both in the headspace and in liquids.

VIDEO

Catalogs

Biology & Environmental Research

20 Pages

Industry & Technical

16 Pages

Medical Research & Life Sciences

20 Pages

Other PreSens Precision Sensing GmbH products

O2 SENSORS

Related Searches

- Medical probe

- Control software

- Temperature probe

- Laboratory software

- Windows software

- Laboratory analyzer

- Monitoring probe

- Data management software

- Measurement software

- Control analyzer

- Gas probe

- Oxygen analyzer

- Flow probe

- Laboratory probe

- Oxygen probe

- Pressure analyzer

- Calibration probe

- PH meter

- CO2 analyzer

- Laboratory pH meter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.