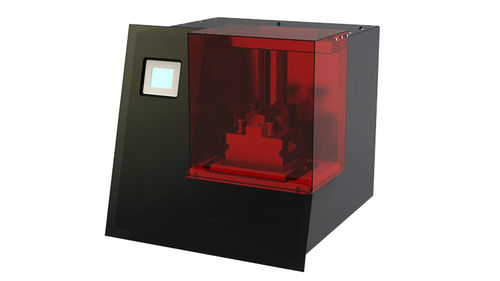

Hearing aid 3D printer HA60tabletop

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for hearing aids

- Configuration

- tabletop

Description

Shell manufacturing in high accuracy and in short batch cycles down to 45 minutes for one full ITE / ITC shell platform.

Ear molds and ear protections in batch cycles down to 60 minutes full platform. Material can be colored or transparent material. Change of material is possible in no time due to easy exchange of the vat.

Multiple times faster than traditional systems with built speed up to 30 mm per hour

Unit passed accuracy qualification processes of large hearing aid manufactures

No lock-in components / Open system architecture

Connectivity with CAD design / support generation software

Open resin library – easy update (online)

Continuous development and customization of resins granted as of open system

Customer side service and maintenance

Installation & training service available

Service-friendly, high quality, long lifetime components

Catalogs

HA60

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.