- Products

- X-ray diffractometer

- Rigaku Corporation

- Products

- Catalogs

- News & Trends

- Exhibitions

X-ray diffractometer MiniFlex XpClaboratory

Add to favorites

Compare this product

Characteristics

- Type

- X-ray

- Applications

- laboratory

Description

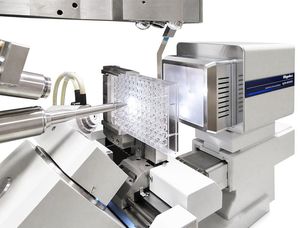

In a move to bring lab-quality performance to the manufacturing floor, Rigaku introduces the MiniFlex XpC, a manufacturing-optimized powder diffractometer for fast and accurate quality control measurements. It is extremely easy to operate using Rigaku’s new EasyX quality control software, which requires minimal clicks to run. A minimal interface means there will be no accidental error variance from operator to operator. The MiniFlex XpC can be configured with a conveyor belt or robot for automated sample processing and collaboration with other instruments. With an 800 W X-ray source and a short-diameter goniometer, the system has the performance of a lab unit, and thus can greatly improve throughput for quality control measurements.

NEW SAMPLE LOADING MECHANISM

The optimal loading mechanism for quality control allows the operator to easily place the sample without opening the instrument door. This system also supports online measurement using a transfer robot. Workers can easily place samples not only online but also offline. A newly designed sample spinner can be used with a variety of sample holders.

HIGHLY DURABLE AND HIGHLY ACCURATE HORIZONTAL GONIOMETER SUITABLE FOR QUALITY CONTROL

Using the technology cultivated with SmartLab, we have developed a new, durable, compact horizontal sample goniometer that is optimal for quality control.

NEW, COMPACT, HIGH-OUTPUT X-RAY GENERATOR

The MiniFlex XpC features a compact molded ceramic X-ray tube. The generator for the X-ray source has also been improved, enabling a high output of 800 W while being almost the same size as the 600 W generator of the MiniFlex desktop X-ray diffractometer.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.