Air filtration system CANWALLfor the pharmaceutical industrywall-mountedstainless steel

Add to favorites

Compare this product

Characteristics

- Type of filtration

- air

- Applications

- for the pharmaceutical industry

- Other characteristics

- wall-mounted, stainless steel

Description

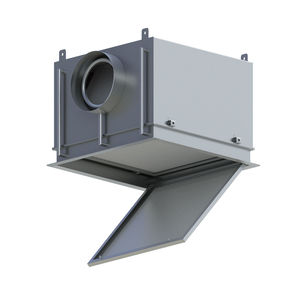

CANWALL safety systems are designed to filter exhaust air from environments containing toxic or harmful contaminants.

These systems are mainly used in industrial, laboratory and process applications and are installed directly in the hazardous environment.

The purpose of these systems is to allow contaminated filters to be replaced with maximum safety for maintenance personnel and the surrounding environment. In the Bag-In/Bag-Out procedure spent filters are sealed inside the barrier bag and then sent for disposal, never coming into contact with any operator.

They consist of a Canister safety system equipped with a SCAN-TEST socket, pressure sockets and a barrier bag, an air intake grille within the environment and a stainless-steel wall with a safety system to avoid accidental falls. Fittings and supports complete the supply.

MATERIAL AND FINISH

The standard version of CANWALL systems includes:

• CANISTER, decontaminable epoxy powder-coated steel fittings and supports

• AISI 304 stainless steel SCAN-TEST sockets for checking filter integrity

• upstream/downstream pressure sockets

• safety bag with ring and incorporated glove

• wall and grille of AISI 304 satin scotch brite stainless steel

OPTIONS

• All components of AISI 304 or AISI 316 L stainless steel

• ATEX II 2 GD T6 version:

– RAL 7021 painted, with stainless steel grille and wall

– all made of stainless steel

• Mirror-polished wall finish

ACCESSORIES

• Air tight Class 4 C damper complying with standard EN 1751

• CANWELD heatsealing sealer

Catalogs

No catalogs are available for this product.

See all of SagiCofim‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.