HEPA filter DUG seriesairfor the pharmaceutical industrystainless steel

Add to favorites

Compare this product

Characteristics

- Filter type

- HEPA

- Fluid

- air

- Applications

- for the pharmaceutical industry

- Material

- stainless steel

- Connection type

- integrated

Description

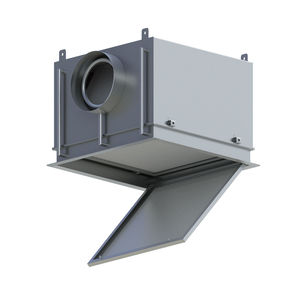

The DUG-B and DUG-A terminal filters are designed to meet the requirements of the strictest cleanliness classes specifically for applications using unidirectional flows.

Their practicality has revolutionised installations into the false ceilings of cleanrooms in the most demanding of industries, where contamination-controlled areas are required (micro-electronics and electronics, pharmaceutical, food, aeronautic and chemical industries).

Integrated DUG-B and DUG-A terminal filters;

Manufactured in an ISO 7 environment, individually scan-tested and packaged in an ISO 5 environment;

Water-repellent, micro-fibreglass filter media;

Equally spaced continuous thermoplastic spacers (mini-pleats);

Bicomponent polyurethane sealant;

Extruded anodised aluminium frame attached to a one-piece plenum made from self-extinguishing, stamp-formed polystyrene or aluminium and with a circular collar;

Painted aluminium protection grid on both sides

On request:

Damper with opposing blades (DR);

External or central leak-test point (T-D);

White EPDM seal (G);

Protection grids in: AISI 304 stainless steel (RRS) / AISI 316 L stainless steel (RRS316);

Micro-perforated diffuser in: aluminium (FL) / AISI 304 (FLS) / AISI 316 L (FLS316);

Flow equaliser on air outlet side (LV);

ATEX 2 GD II T6 (AT), with aluminium plenum only.

Catalogs

DUG-B_DUG-A

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.