- Medical & Pharmaceutical industry

- Medical industry

- Tablet inspection system

- Scanware Electronic

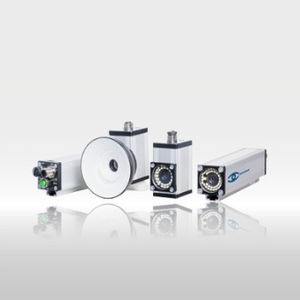

Capsule inspection system SPECTRAbottlefor tablets

Add to favorites

Compare this product

Characteristics

- Applications

- for capsules, bottle, for tablets

Description

The SPECTRA black-and-white blister inspection verifies a number of product-specific criteria of pharmaceutical products – for example presence, position, area and shape as well as overfilling and broken pieces. The black-and-white system is a cost-effective solution for production lines in the pharmaceutical industry where cross-contamination can be ruled out due to technical conditions, such as on mono lines. Software and hardware can be upgraded to colour blister inspection at any time for colour detection.

■Inspection Criteria and Objects

Inspection objects:

Tablets

Oblongs

Dragees

Hard and soft gelatine capsules

Examination criteria:

Presence

Size

Form

Circumference

Position

Fragments

Overfilling

Surface defects

■Advantages of scanware Black and White Inspection

The system offers outstanding speed and excellent statistical analysis tools. All parameters used in the system can be applied simultaneously without impacting speed. If the requirements on site change, the system can be upgraded to the SPECTRA colour system at any time.

The black and white inspection can be used for a number of alternative inspection tasks and offers the user much more than a standard application.

Bottle Inspection

During the forming of plastic bottles, the black & white system inspects the correct edges at the bottle opening and the seam at the bottom of the bottle. The flexible mould is cut off at both ends. Several cameras are used to inspect the cut edges before filling.

Pouch Position Inspection

When filling pouches with powder, contamination and improperly sealed pouches occur due to slanted positions.

Catalogs

Related Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- Tube barcode scanner

- High-speed inspection system

- Vial inspection system

- Capsule inspection system

- Continuous inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- Stand-alone inspection system

- In-line inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.