- Medical & Pharmaceutical industry

- Medical industry

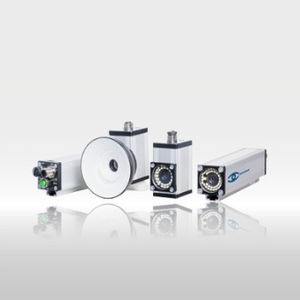

- Optical inspection system

- Scanware Electronic

Optical inspection system SPECTRAautomaticfor capsulesfor tablets

Add to favorites

Compare this product

Characteristics

- Type

- optical

- Operational mode

- automatic

- Applications

- for capsules, for tablets

Description

The SPECTRA Colour optical blister inspection is used to detect cross-contamination, size, position, fragments and overfilling of products on packaging machines. It is the ideal solution for standard inspection tasks in colour. Correctness of the different colours by means of RGB values is displayed in real time – making safety in the packaging process child’s play.

■Inspection Criteria and Objects

Inspection objects:

Tablets

Oblongs

Sugar-coated tablets

Hard and soft gelatine capsules

Examination criteria:

Colour

Presence

Size

Shape

Circumference

Position

Fragments

Overfilling

Surface defects

Serial defects

■Advantages of scanware Colour Recognition

Due to the use of the real-time operating system QNX®, the SPECTRA Colour inspection offers outstanding speed and reliability. All parameters in the colour detection can be applied simultaneously – without loss of function.

The comprehensive analysis options, user-friendly software that can be tailored to your needs and the automatic learning run make it particularly easy to use. In addition, the system can be upgraded at any time to high-resolution SPECTRA High Resolution inspection system to reliably detect not only correct colour but also the most demanding product-film combinations, for example contraceptives.

■Software Facts of Colour Detection

The result on the line is something to be proud of – production and format documentation as well as analysis of lane and cup filling offer you unique opportunities to detect errors in the infeed and reduce ejection. This is made possible by visualisation on the software interface.

VIDEO

Catalogs

Related Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- High-speed inspection system

- Tube barcode scanner

- Continuous inspection system

- Vial inspection system

- Capsule inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- In-line inspection system

- Stand-alone inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.