Manual inspection system SPECTRA Bulk QIcontinuousfor the pharmaceutical industryhigh-speed

Add to favorites

Compare this product

Characteristics

- Operational mode

- manual, continuous

- Applications

- for the pharmaceutical industry

- Other characteristics

- high-speed

Description

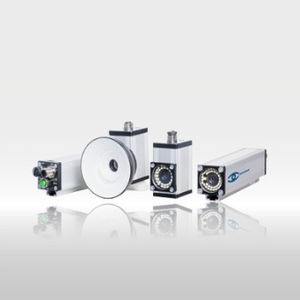

The SPECTRA Bulk QI Inspection system is developed for the detection of wrong colour, broken products and foreign matter in pharmaceutical products packaged in bulk. For this application, the product inspections SPECTRA Colour or SPECTRA High Resolution can be used, either as single or multiple camera solution. This solution can operate on all common slat counters. The quality inspection is continuous right through to the rejection station.

For this application, the new software architecture QI has been implemented which enables extremely high inspection speeds.

■Inspection Criteria and Objects

Inspection objects:

Tablets

Oblongs

Sugar-coated tablets

Hard and soft gelatine capsules

Examination criteria:

Colour

Size

Fragments

Foreign matter

■Advantages of the Bulk Application

The bulk application is carried out with a high-speed inspection of more than 1 million products per hour and performs detailed defect detection with a multi-camera solution. The high-resolution SPECTRA Bulk QI can be used on all common tablet counting machines (slat counters) and on all common counting machines (ETC) with vibration feed. The use on large machine widths can be inspected.

SPECTRA Bulk QI supports the following production modes: ejection of individual products, ejection of bottles after filling, and manual removal of bad products.

Up to 48 vibration channels can be inspected. With this application, detection of foreign products, fragments and foreign bodies can be accomplished. In addition, this solution offers position-accurate evaluation for individual ejections.

Catalogs

Bulk

2 Pages

Related Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- High-speed inspection system

- Tube barcode scanner

- Continuous inspection system

- Vial inspection system

- Capsule inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- In-line inspection system

- Stand-alone inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.