Inspection system for the pharmaceutical industry SPECTRA Japan Qualityhigh-speed

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for the pharmaceutical industry

- Other characteristics

- high-speed

Description

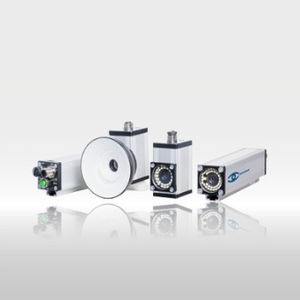

The blister inspection SPECTRA Japan Quality offers the highest image resolutions for high-speed evaluation. This makes it the optimal system for high demands such as those of the Japanese pharmaceutical market, which requires visually flawless products due to cultural conditions, as consumers perceive external minimal defects as serious reasons for rejection.

The colour system continuously distinguishes 16 million colours even in three-shift operation at high-speed. For Japan Quality Product Inspection, a water-cooling system is employed to keep the cameras at optimum temperature. Offering the same resolution at high speed,

this enables the detection of minimal flaws and tiny defects.

■Inspection Criteria and Objects

Inspection objects:

Tablets

Oblongs

Dragees

Hard and soft gelatine capsules

Special forms

Sealed products

Examination criteria:

Smallest contaminants such as e.g.

Painting defects

particles on the tablet or lacquer

Surface defects

Additional examination criteria:

Colour

Presence

Size

Shape

Position

Circumference

Fragments

Overfill

Serial defects

■Advantages of the Japan Quality Application

Hardware and software are selected with the demands of the Japanese market in mind. Japanese goods in general are subject to very high standards of uniformity and standardisation. The consumer’s critical eye, thus sharpened, also questions the correctness of the processes and thus the product as such in the case of external flaws. Thus, the appearance of the product becomes just as decisive a criterion for producers for the Japanese market as harmlessness and efficacy.

Catalogs

Japan Quality (HR)

4 Pages

Related Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- High-speed inspection system

- Tube barcode scanner

- Continuous inspection system

- Vial inspection system

- Capsule inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- In-line inspection system

- Stand-alone inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.