- Medical & Pharmaceutical industry

- Medical industry

- Scanware Electronic

Tube inspection system SIGNUM

Add to favorites

Compare this product

Characteristics

- Applications

- for tubes

Description

The SIGNUM Tube 1DC tube inspection takes place between tube infeed and tube filling. The system checks printed one-dimensional codes, both single and multi-coloured, as well as print marks on aluminium and plastic tubes. This prevents tubes with incorrect printing from being filled in the first place and increases productivity on the line.

Inspection criteria and objects

Testable objects:

Aluminium tubes

Plastic tubes

Test criteria

Pharmacode

Mini Pharmacode

Printing marks

■Advantages of 1DC tube inspection

Integration into the newest QI visualisation

Visualisation of the current reading and a history of the 15 previous results

Ideal add-on to existing packaging lines

Good and bad signals are evaluated using signals in the integrated shift register

Extraordinarily high speed and reaction time after the reading

■Facts of the 1DC tube inspection solution

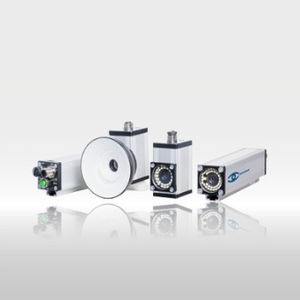

The SIGNUM Tube 1DC application is carried out by the SIGNUM 1DC one-dimensional code inspection system. Pharmacodes, minipharmacodes and print marks printed on tubes are checked.

Software

Pharmacodes, minipharmacodes and print marks can be read by making the appropriate settings in the menu selection, which is designed to be particularly user-friendly and is linked to the latest QI software architecture.

The reading result is transmitted in real time to the machine control. The reading of printed pharmaceutical codes can be carried out with this code reader at positions where a camera solution is not possible.

Distortions of the code, which can occur due to the curvature of the tube, are compensated for by the software.

Catalogs

Codes (1DC / 2DC)

4 Pages

Related Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- High-speed inspection system

- Tube barcode scanner

- Continuous inspection system

- Vial inspection system

- Capsule inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- In-line inspection system

- Stand-alone inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.