- Medical & Pharmaceutical industry

- Medical industry

- Automatic inspection system

- Scanware Electronic

Automatic inspection system 360° Orbitalcontinuousbottle

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic, continuous

- Applications

- bottle

Description

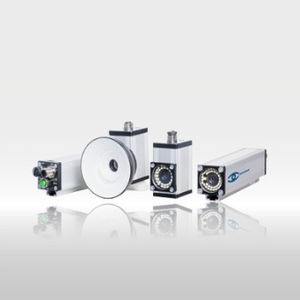

CAPA 360° Orbital is a 360° inspection system used for the inspection and reading of 2D and auxiliary codes on pharmaceutical, reclosable plastic bottles. The orbital inspection enables thanks to

Thanks to the 360° reading range, the orbital inspection system enables all-round quality assurance of the arbitrarily shaped object as well as a printing, serialisation and aggregation function for the printed codes.

CAPA 360° Orbital is used in the packaging process and is the solution for the use of auxiliary codes in the course of aggregation. The printing of the auxiliary codes and their reading and linking with the serial number on the bottle label are the prerequisites for the aggregation of the products in the fully automatic case packer.

■Examination criteria and objects

Objects:

Plastic bottles

Criteria:

2D codes: Printing and evaluation

UV auxiliary codes: Printing and reading

Bottle cap and label: Inspection of correct fit

■Advantages of the 360° Orbital Station

A high-resolution 6x camera system of the latest technology generation

Fully serialisable

Aggregation in a can bundle packer or toploader possible

Integration of the Continuous Ink Jet (CIJ) printers commonly used on the market for auxiliary code printing

Maximum output of 120 bottles per minute

Equipped with W-LEDs and UV illumination

Optimum conveyor speed ensures minimum distance between bottles

Integrated bottle separation, which can also be used for downstream machines

Full integration of all switch and control cabinets

Equipped with a jam control at the infeed and discharge of the machine

Catalogs

No catalogs are available for this product.

See all of Scanware Electronic‘s catalogsRelated Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- High-speed inspection system

- Tube barcode scanner

- Continuous inspection system

- Vial inspection system

- Capsule inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- In-line inspection system

- Stand-alone inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.