- Medical & Pharmaceutical industry

- Medical industry

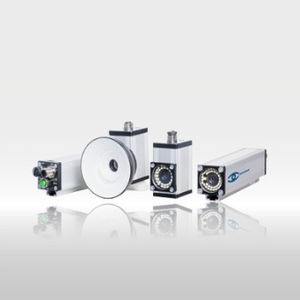

- Automatic inspection system

- Scanware Electronic

Automatic inspection system for the pharmaceutical industryfor folding boxesstand-alone

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for the pharmaceutical industry, for folding boxes

- Other characteristics

- stand-alone, with marking

Description

To ensure the safety of pharmaceutical products along the entire supply chain, the folding boxes are marked with serialised data as part of Track & Trace. The correctness of the data is then verified and returned to the database.

As a specialist for quality assurance in the pharmaceutical industry with more than 30 years of experience, scanware offers you solutions designed for the packaging process within the scope of Track & Trace applications.

The CAPA Mark & Verify station is a stand-alone design for Mark & Verify on your line that can be adapted to your needs. The processing and aggregation of serialised data is implemented by scanware’s line manager IMPERA.

■Inspection Criteria and Objects

Examination criteria:

1D and 2D codes such as Code 128, DataMatrix and Krypo Code

Plain text such as batch number, expiry date, GTIN and serial number

Advantages of the Mark & Verify Station

Implementation of all common encodings and printers

Precise printing and high-performance print inspection

High-quality standard components and thus efficient spare parts supply

Uniform user interface, comprehensible menu navigation and convenient data entry

Adaptable to different lines

Can be retrofitted if your needs or regulations such as EU Directive 2011/62/EU change

Tool-free adaptation to the size of the box

Robust construction, movable and ergonomic, as well as easy to clean

Excellent power transmission through the use of planetary gears and wear-free drives through brushless motors

Combinations of different systems for more Track & Trace variety

VIDEO

Catalogs

No catalogs are available for this product.

See all of Scanware Electronic‘s catalogsRelated Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- High-speed inspection system

- Tube barcode scanner

- Continuous inspection system

- Vial inspection system

- Capsule inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- In-line inspection system

- Stand-alone inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.