- Medical & Pharmaceutical industry

- Medical industry

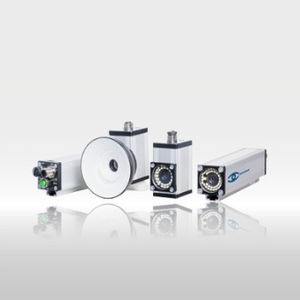

- Automatic inspection system

- Scanware Electronic

Automatic inspection system Tamper Evidencefor the pharmaceutical industryfor folding boxeswith automatic labeling

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for the pharmaceutical industry, for folding boxes

- Other characteristics

- with automatic labeling

Description

In order to ensure the safety of pharmaceutical products along the entire supply chain, more and more packaging units are being provided with tamper-evident seals to prevent the distribution of counterfeit medicines. In the context of Track & Trace, this is an important step, in addition to labelling and data processing, in which scanware, as a specialist for quality assurance in the pharmaceutical industry with more than 30 years of experience, is reliably at your side.

With CAPA Tamper Evidence scanware offers a flexible station at which pharmaceutical packaging is sealed with tamper-evident labels. Various functionalities can also be integrated. The use of clear, fluorescent tamper-evident labels on the sides is standard.

Particularly in the case of prescription-only medicines, the highest level of security can be ensured by serialisation, aggregation and end-to-end inspection of the production and distribution data. Here, the processing of serialised and aggregated data can be made possible by using the line manager IMPERA.

■Inspection Criteria and Objects

Examination criteria:

Presence of labels

Position of labels

Optional examination criteria:

Label printing (1D and 2D codes as well as plain text)

■Advantages of the Tamper Evidence Station

High positioning accuracy of the Tamper-Evidence labels through precise object guidance and optimal use of sensors.

Adjustment to the size of the carton is tool-free. Operation is only from the front; there are no walking distances. Likewise, the label reels can be changed while the machine is running, so that productivity on the line remains constantly high.

VIDEO

Catalogs

TRACK & TRACE

2 Pages

Related Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- High-speed inspection system

- Tube barcode scanner

- Continuous inspection system

- Vial inspection system

- Capsule inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- In-line inspection system

- Stand-alone inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.