- Medical & Pharmaceutical industry

- Medical industry

- Automatic inspection system

- Scanware Electronic

Automatic inspection system Case (CI)for the pharmaceutical industryfor boxesbundle

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for the pharmaceutical industry, for boxes, bundle

- Other characteristics

- stand-alone

Description

To ensure the counterfeit protection of pharmaceutical products, the folding boxes packed in shipping boxes are inspected and the data processed as part of Track & Trace.

At the CAPA Case control station, printed images of folding boxes, bundles and shipping boxes are inspected and compared with database entries. This can be integrated as a stand-alone construction for case inspection on your line or in case packers.

The processing and aggregation of serialised data is implemented by scanware’s line manager IMPERA.

■Inspection Criteria and Objects

Examination criteria:

Readability of 1D and 2D codes such as Code 128, DataMatrix and Crypto Code

■Advantages of Case Inspection

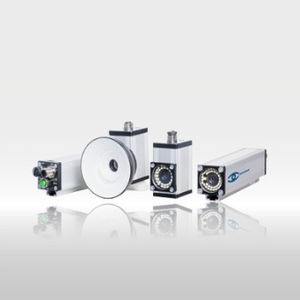

High camera resolution for optimal results

Automatic adjustment of camera and light module when changing layers

Adjustable positioning edge to hold the shipping box in place

Implementation of all common codings

High-performance print inspection

High-quality standard components and thus efficient spare parts supply

Uniform user interface, comprehensible menu navigation and convenient data entry

Can be retrofitted if your requirements or regulations such as EU Directive 2011/62/EU change

Robust construction, mobile and ergonomic, and easy to clean

Excellent power transmission through the use of planetary gears and wear-free drives through brushless motors

Fully serialisable

Aggregation possible

■Functionalities of the Case Inspection

Print inspection

The print is inspected by area scan cameras with integrated illumination. The method used for reading characters and codes was developed by scanware, is feature-based and optimised for high reading performance.

Catalogs

No catalogs are available for this product.

See all of Scanware Electronic‘s catalogsRelated Searches

- 2D barcode scanner

- 1D barcode reader

- Inspection system for the pharmaceutical industry

- Automated inspection system

- Laboratory barcode reader

- Optical inspection system

- Compact inspection system

- Bottle inspection system

- High-speed inspection system

- Tube barcode scanner

- Continuous inspection system

- Vial inspection system

- Capsule inspection system

- Manual inspection system

- Tablet inspection system

- Ampoule inspection system

- In-line inspection system

- Stand-alone inspection system

- Inspection system with printing system

- Syringe inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.