- Dental

- Dental practice

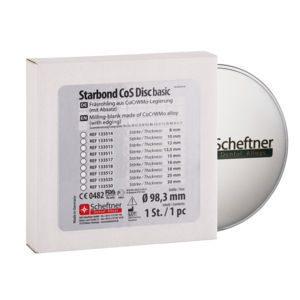

- CoCrMo dental material

- scheftner dental

CoCrMo dental material Fusionis Discfor dental restorationsCAD/CAMmilling

Add to favorites

Compare this product

Characteristics

- Type

- CoCrMo

- Applications

- for dental restorations, CAD/CAM, milling, for denture making

- Other characteristics

- biocompatible

Description

CoCrMo milling disc for the production of fixed and removable dentures. The alloy properties, the quality and excellent milling results make Fusionis Disc the material of choice. The ideal material for the unique manufacture of removable partial dentures with clasps and retainers, telescope dentures, bars and attachments in CAD/CAM processes. Free of nickel, beryllium, lead and cadmium. Type 4 pursuant to DIN EN ISO 22674.

Advantages for users:

Excellent machinability, validated process

Ideal mechanical properties

Average hardness of 290 HV 10

Extremly corrosion resistant

Excellent polishability and easy to use

Laser weldable

Composition in percent by mass:

Co - 63%

Cr - 29%

Mo - 5%

C,Si,Nb,Mn,Fe - <1%

Technical properties:

Proof stress (Rp 0.2) - 420MPa

Ultimate tensile strength - 650MPa

Elongation - 10%

Elastic modulus - 210GPa

Vickers hardness - 290HV10

Density - 8.3g/cm³

Laser weldable - Yes

Type (DIN EN ISO 22674) - 4

Catalogs

Catalogue

35 Pages

Other scheftner dental products

Non-precious metal milling discs (NPM)

Related Searches

- Dental material

- Restoration dental material

- Dental prosthesis dental material

- Modeling dental material

- Dental crown material

- Ceramic dental material

- Dental bridge material

- Biocompatible dental material

- Wax dental material

- Casting dental material

- Dental CAD/CAM material

- Milling dental material

- Dental laboratory dental material

- 3D printing dental material

- Silicone dental material

- Alloy dental material

- Powder dental material

- Implant system material

- Denture making dental material

- Metal dental material

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.