Website:

Shandong Liangyi Medical Instrument

Website:

Shandong Liangyi Medical Instrument

All Shandong Liangyi Medical Instrument products

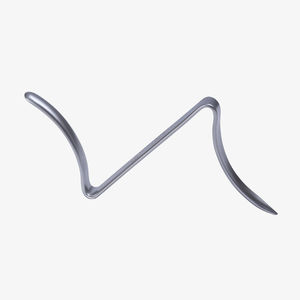

Knee Joint

Hip Joint

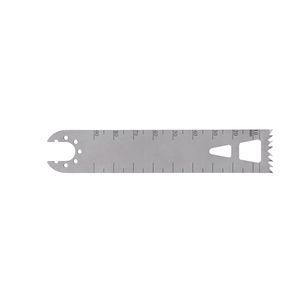

Saw Blade

Dedicated Saw Blade for Joint Surgical Robot

Orthopedic surgical Robots

Remove all

Compare up to 10 products