- Products

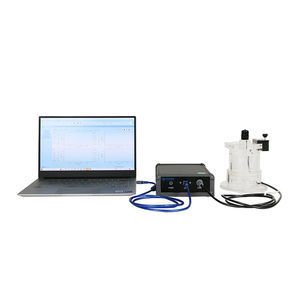

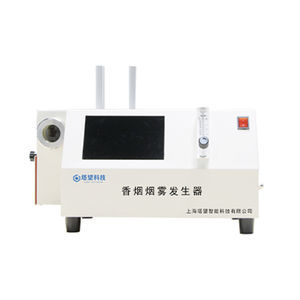

- Laboratory aerosol generator

- Shanghai TOW Intelligent Technology

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Laboratory aerosol generator Collisonportableatomizer

Add to favorites

Compare this product

Characteristics

- Applications

- laboratory

- Configuration

- portable

- Technology

- atomizer

Description

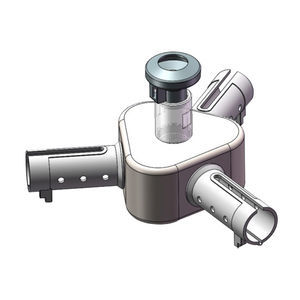

The atomization method used in Collison aerosol generators relies on Bernoulli’s principle. When air passes through the nebulizer’s holes at high speed, it draws liquid from the can and breaks it down into small droplets. This atomized liquid then hits the tank’s wall, creating smaller droplets. Larger particles are removed from aerosols using specially designed traps or curved outlet pipes.

Product Description

The atomization method used in Collison aerosol generators relies on Bernoulli’s principle. When air passes through the nebulizer’s holes at high speed, it draws liquid from the can and breaks it down into small droplets. This atomized liquid then hits the tank’s wall, creating smaller droplets. Larger particles are removed from aerosols using specially designed traps or curved outlet pipes.

Collison aerosol generator has its standard for the glass jar: crushing-resistant polycarbonate, polyetherimide (ULTEM), and polysulfone tanks are optional to provide maximum protection against accidental exposure due to high stress or temperature conditions. In addition, 316 stainless steel tanks are available to ensure maximum durability and safety standards in special applications. Alternatively, an optional high-temperature resistant model is available.

The Collison atomizer is optionally fitted with the Precious Fluids Jar, which has a 5 ml hole at the bottom to save costly samples. The extension sleeve is pushed through the end of the Collison nozzle and dipped into the well. Using an extension sleeve, the nozzle is kept high so the output can properly hit the can.

Catalogs

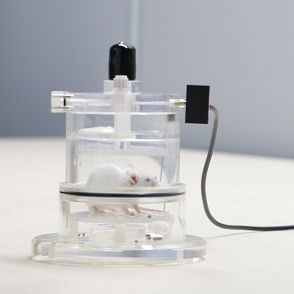

Whole Body Exposure System

32 Pages

Other Shanghai TOW Intelligent Technology products

Respiratory Research

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.