- Hygiene

- Sterilization

- Sigma Medical Supplies

- Products

- Catalogs

- News & Trends

- Exhibitions

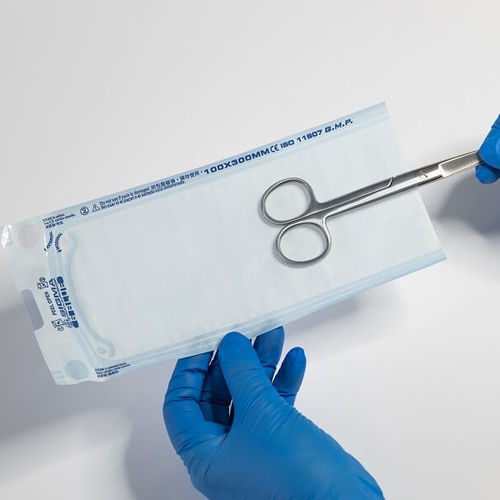

Sterilization pouch

Add to favorites

Compare this product

Description

SIGMA Flat/Gusseted Heat-Sealing Pouches are made by high-quality medical paper and reinforced film. The sealing edges are designed with multiple sealing lines, and the opening is designed with a herringbone seal, both of which can reduce the risk of breakage from sharp edged medical devices and maintain the integrity of the seal after the sterilization.

Depending on the heat resistance, medical paper is divided into two types according to the sterilization method: Steam & EO, and EO & Plasma, while Flat Heat-Sealing Pouches can be used for Steam & EO sterilization. Lead-free and non-toxic water ink is used to print indicators on the inner and outer edges of both pouches, which changes color with different sterilization methods and has color change indication so that users can clearly identify the sterilization status.

Depending on the grammage, both medical papers are available in 60g with blue reinforced film and 70g with green reinforced film. The transparent film makes it easy for the user to identify the contents within the packaging.

Comply with international regulations such as FDA, EN 868, ISO 11607, and ISO 111401-1

SIGMA has the highest quality control systems for each procedure, including product development, design, quality inspection and marketing. With extensive experience in customized manufacturing, we design, develop and produce according to customers’ requirement.

Features

Provides an effective sterile barrier and prevents medical devices from cross infection.

Tyvek® paper with air permeability, anti-bacterial, waterproof, and leakproof.

Applies non-toxic ink and de-ink prevention technology.

Exhibitions

Meet this supplier at the following exhibition(s):

Other Sigma Medical Supplies products

Hospitals & Dental Services

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.