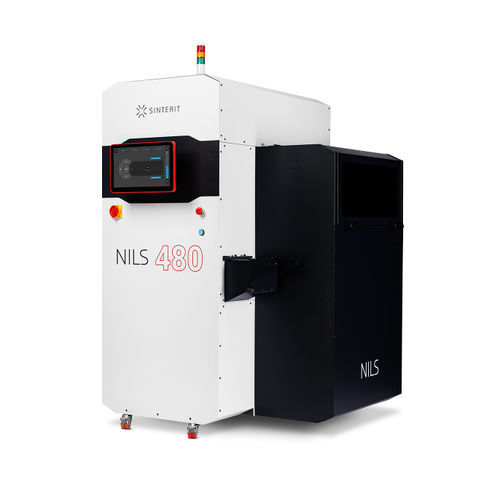

Medical 3D printer NILS 480SLS

Add to favorites

Compare this product

Characteristics

- Applications

- medical

- Technology

- SLS

Description

With its Continous Printing and Automatic Powder Dispensing Systems, you can do the same work much more efficiently. If you print a lot, these features really matter.

The NILS 480 is equipped with the Galvo laser scanning system. This means most printing jobs can be finished within 24 hours.

The NILS 480 meets the industrial market standard for size, enabling you to print much more at lower prices per part.

With the speed, build size and automated work the NILS brings, you achieve superior ROI in an industrial SLS printer – in as little as 40 days.

With this solution, fill the powder once and print two full beds or a few lower print beds. All of this without repeating the print preparation process and powder filling. How does the NILS do this? The previous bed automatically ejects, lifting a full cake to the cooling box. The printing bed comes back and another print automatically begins.

With automated systems, an effective ecosystem with post-processing, and easy material change, you can be sure the printing experience will be smooth and simple.

Just fill the container with powder and let the printer manage the rest of the process. This is possible thanks to the special closed powder circuit, which circulates the powder and automates the powder dispensing. No manual work with powder is required until you receive the final print cake.

Catalogs

No catalogs are available for this product.

See all of Sinterit‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.