- Hygiene

- Sterilization

- CSSD sterilizer

- Siriusmed

- Products

- Catalogs

- News & Trends

- Exhibitions

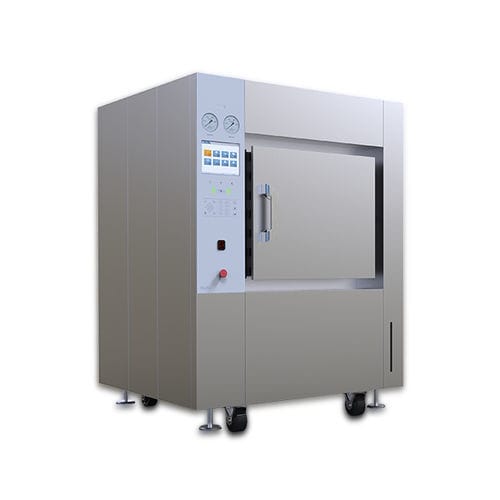

Medical sterilizer HS-360surgicalCSSDsteam

Add to favorites

Compare this product

Characteristics

- Applications

- medical, surgical, CSSD

- Sterilization procedure

- steam

- Configuration

- floor-standing

- Function

- automatic

- Sterilization chamber material

- stainless steel

- Temperature range

Min.: 132 °C

(269.6 °F)Max.: 134 °C

(273.2 °F)- Sterilization cycle time

166 min

Description

Pulsation vacuum sterilizers (motorized door), a series of advanced sterilizers developed and produced by our company according to the latest national standard- "Technical Requirements for Large-Scale Steam Sterilizer (an Automatic Control Type)”, are fully in line with the CSSD, and GMP regulatory requirements of the sterilization device. The series can be large steam sterilizers require available for the sterilization of medical, pharmaceutical, research institutions, surgical instruments, dressings, fabrics.

Design concept:

Pulsating vacuum sterilizer, with the saturated steam as the sterilization medium and in the air exclusion method of mechanical forced pulsating vacuum, makes the air inside excluded by the alternation of vacuuming and injecting steam repeatedly and completely eliminates the cold points in the sterilizing chamber; so that the air exclusion volume can reach 90% or more and the temperature “dead ends” and “small amount effect” can be completely eliminated, ensuring the thorough sterilization effect. The vacuum dehumidifiers make the sterilization chamber evacuated to the negative pressure of the vacuum pump limit vacuum, and dry it with the fixture of the sterilizer in the high temperature, so the objects after sterilization can be dry and clean and when removing them, your hands will not be wetted or burned.

Significance of the composition of the models and their representatives:

H S XXX W (C)

carbon steel pipeline

sanitary piping

available space of sterilization chamber

Catalogs

No catalogs are available for this product.

See all of Siriusmed‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.