- Dental

- Dental practice

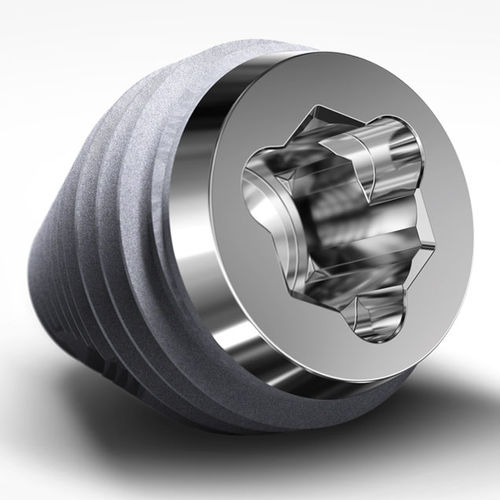

- Conical dental implant

- SOUTHERN IMPLANTS (Pty) Ltd.

Tapered dental implant TRI-MAX®titaniuminternal octagon

Add to favorites

Compare this product

Characteristics

- Shape

- tapered

- Material

- titanium

- Connection

- internal octagon

- Implant diameter

7 mm, 8 mm, 9 mm

(0.28 in, 0.31 in, 0.35 in)- Implant length

7 mm, 9 mm, 11 mm

(0.28 in, 0.35 in, 0.43 in)

Description

Challenge

A conventional implant is not suited for immediate placement in the molar extraction socket. As a result, waiting periods of three to four months are necessary to allow for healing of the socket prior to implant placement. Often, the healed extraction site presents reduced bone height, inadequate for implant placement without a bone augmentation procedure.

Innovation

The award-winning MAX dental implant systems feature a body with a larger-than-conventional diameter to fill the molar site, ultimately achieving primary stability from engagement with the inter-radicular bone.. With tapered dental implant bodies and an enhanced surface, the MAX tapered dental implant is designed to fit the natural shape of the molar socket. The end result is an optimal implant fit in the multi-rooted immediate extraction site that minimizes bone loss and reduces treatment time.

Awards

American Academy of Osseointegration (AO) – Best Innovation Award, 2008

The SABS – Design Excellence Award – Medical Devices, 2010

Technical Facts

7mm, 8mm and 9mm diameter, (6mm diameter External Hex MSc only)

Greater degree of taper

7mm, 9mm, and 11mm lengths

Enhanced surface

Available in External Hex, Internal Hex TRI-NEX® and Internal Octagon connections

Surgical and Prosthetic Benefits

Fits multi-rooted molar socket and allows for immediate placement following extraction

Maximizes bone preservation

Minimizes need for bone grafting

Avoids adjacent tooth roots

Increases patient acceptance

Reduces treatment time

Ability to use standard surgical protocol and instrumentation with minimal additions

Ability to use compatible prosthetic components by “platform switching”

Catalogs

TRI-NEX

52 Pages

Other SOUTHERN IMPLANTS (Pty) Ltd. products

Dental Implant Connections

Related Searches

- Implant abutment

- Titanium implant abutment

- Straight implant abutment

- Internal implant abutment

- Dental implant

- Titanium dental implant

- Hexagonal implant abutment

- Screw implant abutment

- Angulated implant abutment

- Internal hexagon implant abutment

- Bone substitute

- Dental implant analog

- Tapered dental implant

- Straight dental implant analog

- Cylindrical dental implant

- Hexagonal dental implant

- Internal hexagon dental implant

- MUA implant abutment

- Dental driver

- Cemented implant abutment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.