- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

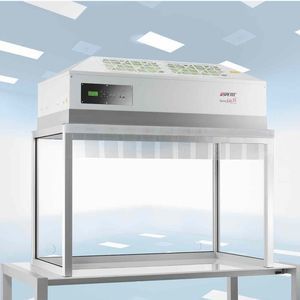

Clean room laminar flow module FBS-V seriesceiling

Add to favorites

Compare this product

Characteristics

- Applications

- for clean rooms

- Configuration

- ceiling

Description

FBS-V series models consist of a laminar flow module FMS and a PVC clean room strip curtain.

The PVC strip curtain which hangs down from the laminar flow module is adjusted so that its ends are flush with the device housing. Thanks to the laminar flow of air, there is no mixing of dirty ambient air.

The laminar flow module is attached to the building‘s ceiling with ceiling hangers. The curtain prevents the entry of dirty air when people walk by or transport vehicles drive by. In general, this system is used to create localized clean room conditions at machines or instruments which are too big to place them inside a box. In addition, assembly workstations can also be enclosed.

Control panel

The flow velocity can be controlled in 8 steps. The controls include the “night reduction” (eco) mode to save energy costs, and the “MAX” function to clean the workstation, parts, or equipment if applicable.

8 level adjustment of the flow velocity with night reduction and flushing function

LCD display with selected flow velocity in m/second

Automatic flow adjustment with filter replacement indicator (optional)

LED fault indicator

Interior light switch on the control panel (optional)

Service and interval indicator, dependent on the usage period

Catalogs

Brochure Cleanroom Technology

28 Pages

Spetec® Clean room technology

38 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.