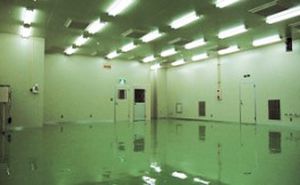

- Medical & Pharmaceutical industry

- Medical industry

- Injection molding machine

- Sumitomo Heavy Industries

Medical device manufacturing injection molding machine SE-EV-A-SHR

Add to favorites

Compare this product

Characteristics

- Applications

- for medical device manufacturing

- Clamping force

Min.: 500 kN

Max.: 1,800 kN

Description

Can be achieved by improving filling speed and through high response acceleration and deceleration

By shortening the screw stroke required to reach the setting speed, the followability relative to the set conditions is improved.

Since the deceleration capabilities are also similarly improved, it is possible to maintain high fill speeds until right before the target position. This helps minimize molding defects seen in thin-walled molding.

Multiple cavities

With enhanced injection speed, before the melt flow solidifies the narrow cavity can be filled.

Shorten the sprue and the runner

Because the target speed range is reached in a shorter time, the sprue and runner sizes can be reduced.

Reducing warpage and deformation

With improved deceleration capability, it can maintain high speed until right before the target. Warpage and deformation can be reduced.

Refined multiple stages control

It’s capable of utilizing multi stage settings for both position and clamp force to best match the thin-walled or thick-walled products. Adjusting for warpage or proper product release as well as reducing birefringence to increase product quality and productivity is possible.

VIDEO

Catalogs

SE-EV-A-SHR

4 Pages

Other Sumitomo Heavy Industries products

Industrial Machinery

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.