- Medical & Pharmaceutical industry

- Medical industry

- Injection molding machine

- Sumitomo Heavy Industries

Medical device manufacturing injection molding machine SE-HSZ

Add to favorites

Compare this product

Characteristics

- Applications

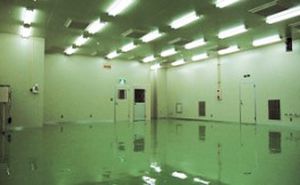

- for medical device manufacturing

- Clamping force

Min.: 1,000 kN

Max.: 1,800 kN

Description

Specially equipped with a linear guide and anti-shock leveling pads ideal for fast cycle molding,

with a focus on Zero-molding to improve consistency of production. Thin-wall, fast cycle and stable molding realized.

The apex of stable and fast-cycle molding

Fast cycle molding far surpassing the performance of conventional models, thanks to improved injection speed, better responsiveness,

shorter process time, and precise control. Machine high performance enables comfortable, fast cycle production.

Zero-molding, first time introduced as standard feature,

has won “tender and easy” to molds widely.

Achieves an average of 15% cycle time reduction when compared to conventional model through improved injection speed,

FFC molding, and faster mold open and close via ISC. For FFC (flow front control) molding,

extra holidng time previously required to prevent sink marks can now be reduced to zero, which contributes to productivity.

ISC (intelligent servo control) system for improving productivity

Faster mold open/close realized, reduced machine vibration, and improved molding stability through use of a new control algorithm.

Improved servo control performance reduces variation in cushion position and peak pressure, enabling precise plasticizing, filling, and holding process.

Catalogs

Packaging Series

10 Pages

Other Sumitomo Heavy Industries products

Industrial Machinery

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.