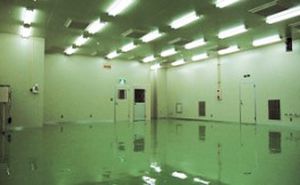

- Medical & Pharmaceutical industry

- Medical industry

- Injection molding machine

- Sumitomo Heavy Industries

Medical device manufacturing injection molding machine SE-EV-S

Add to favorites

Compare this product

Characteristics

- Applications

- for medical device manufacturing

Description

The injection molding machine for lens adopts specially structured

Thermal Free Platens that minimize any irregular deformation due to heat,resulting in a platen that keep platen parallelism and straightness.

Specialized for connector molding

Plasticizing unit designed

for connectors

The specially designed plasticizing unit stabilizes dosing and shot consistency, which greatly reduces dosing time and part weight fluctuations. Even if the regrind ratio is increased, the dosing remains stable.

The result is a yield improvement to reduce material costs.

Helps to reduce costs and improve productivity

FTCIII nozzle

The FTCIII nozzle prevents stringing and clogging by evenly distributed temperature using 2-zone temperature control.

Additionally, with its long reach, it reduces the amount of sprue plastic material and shortens the mold opening stroke, which leads to a faster cycle.

Moreover, the nozzle can be detached quickly and easily, which facilitates cleaning and shortens machine down time.

Catalogs

No catalogs are available for this product.

See all of Sumitomo Heavy Industries‘s catalogsOther Sumitomo Heavy Industries products

Industrial Machinery

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.