- Primary care

- General practice

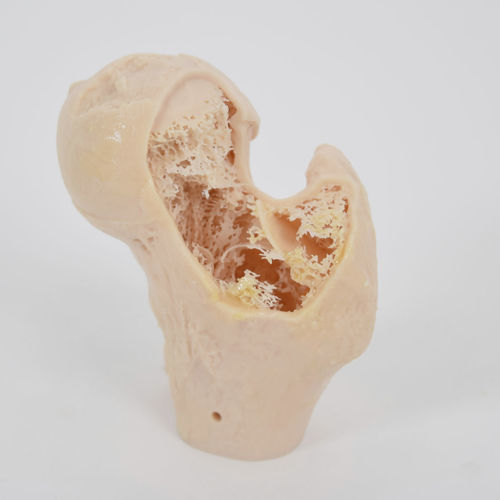

- Bone model

- SYNBONE AG

Bone model orthopedic surgerytrainingpolyurethane

Add to favorites

Compare this product

Characteristics

- Area of the body

- bone

- Application

- orthopedic surgery

- Procedure

- training

- Material

- polyurethane, foam

- Other characteristics

- large

Description

SYNBONE’s anatomical models are manufactured with a specially formulated polyurethane foam comprising of a cancellous inner core and a harder outer shell simulating the cortical bone. They are primarily developed for orthopaedic surgical education and are designed to provide the feeling of working with humanlike bone. Similar forces are required to saw, tap, plate and drill our models.

Although the SYNBONE’s do not have the same biomechanical properties of natural bone, which is stronger than the SYNBONES due to its complex composition, the feedback is very positive from a number of biomechanical testing facilities that have compared our bone models with real bones.

During ballistic testings SYNBONE’s fracture in a manner very similar to natural bones providing an excellent reproducible simulation. SYNBONES provide the excellent mechanical properties of natural bone.

Mechanical Properties

The handling properties of SYNBONE closely simulate those of real bones and are achieved by complex design, moulding and production techniques. They can be cut, drilled, tapped and modified by all available orthopaedic instruments. Even complex fractures and pathological conditions may be mass produced enabling training in large scale surgical skill courses.

Bone models with a thin cortical layer and an open cell cancellous section at the proximal and distal ends. The properties of the inlay allow all application techniques of cement injection. All models may be fractured and delivered with defects on request.

Catalogs

No catalogs are available for this product.

See all of SYNBONE AG‘s catalogsRelated Searches

- Anatomy model

- Demonstration anatomical model

- Teaching anatomy model

- Surgical anatomical model

- Bone anatomical model

- Intracranial anatomical model

- Flexible anatomical model

- Plastic anatomy model

- Dental anatomical model

- Whole body anatomical model

- Vertebral column model

- Pelvic anatomical model

- Orthopedic surgery model

- Skeleton anatomy model

- Anatomical model with nerves

- Veterinary anatomical model

- Implantology anatomical model

- Foam anatomical model

- Arm anatomical model

- Polyurethane anatomical model

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.