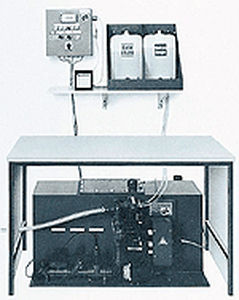

Neutralization water treatment system TC 2000

Add to favorites

Compare this product

Characteristics

- Technology

- neutralization

Description

The chemically contaminated wastewater flows freely into the wastewater storage tank and is fed into the neutralisation system by a centrifugal pump and solenoid valve.

Level sensors control and monitor the filling level in the wastewater storage tank and in the neutralisation tank and also prevent the pump from running dry.

When the maximum filling level in the neutralisation tank is reached, the inlet valve is closed. At the same time, the mixing channel pump of the neutralisation system is switched on. Circulation now takes place in the neutralisation tank in order to determine an exact measured pH value (variably adjustable). After the specified time has elapsed and the set pH value has been reached, the water is pumped into the canal.

A pH electrode in the intake pipe of the special pump continuously determines the pH value. This is visibly displayed digitally on the switchboard.

If the neutral pH value is not reached after the circulation time, lye or acid is dosed by electromagnetic diaphragm dosing pumps. The acid and lye tanks are monitored by level switches. When the minimum filling level is reached, there is an optical and acoustic signal. The dosing process is interrupted.

By permanently measuring the pH value and adding lye or acid at intervals, the feared overturning is avoided.

A pH combination electrode in the suction line of the mixing channel pump constantly determines the pH value. This is visibly displayed digitally on the control cabinet. Once the neutral pH value is reached, a variably adjustable remixing time takes place. After this, the neutralised waste water is pumped into the discharge pipe.

Catalogs

TC 2000

2 Pages

Related Searches

- Tritec cabinet refrigerator

- Tritec 1-door refrigerator

- Tritec automatic defrost refrigerator

- Tritec refrigerator with glass door

- Tritec pharmacy refrigerator

- Tritec electric refrigerator

- Tritec stainless steel refrigerator

- Tritec 2-door refrigerator

- Tritec hospital refrigerator

- Tritec air-cooled refrigerator

- Tritec 3-door refrigerator

- Bench-top refrigerator

- Healthcare facility water treatment system

- Tritec refrigerator with independent circuits

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.