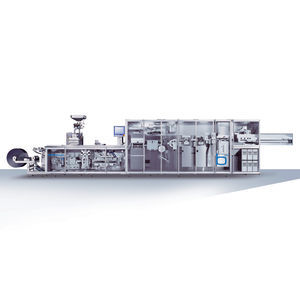

Automated packaging machine BLU 400floor-standingcompactsolids

Add to favorites

Compare this product

Characteristics

- Operational mode

- automated

- Configuration

- floor-standing, compact

- Product applications

- solids

- Container type

- blister

- Application domain

- for the pharmaceutical industry

- Options

- sealing

- Production capacity

400 p/min

Description

The BLU 400 handles the pharmaceutical packaging of ampoules, syringes, vials, bottles, cartridges, or pens in blister packs. The compact packaging machine meets all the essential requirements of the pharmaceutical market for the secondary packaging of parenteral products. As a fully automated packaging system, the BLU 400 offers a convincing performance based on reliable, gentle product handling and flexible, cost-efficient packaging.

The BLU 400 for the gentle packaging of parenteral products

The packaging of parenteral products is no easy task in general as the small glass receptacles are susceptible to damage, particularly when glass-glass or glass-metal contact occurs. Should a product break, cleaning is much more laborious than with solids. This factor places high demands on the packaging machine.

The Uhlmann Blister machine BLU 400 meets all the key requirements of the secondary packaging of parenteral products.

Gentle

Very careful handling avoids damage to the parenteral products, e.g., minimum drop heights in the feeder, or integrated product position control in the press-in and sealing station.

Straightforward

Intuitive operation of the blister packaging machine and easy, guided format changeovers with the SmartControl operating system.

Flexible

Whether feeder, fill section, transfer, or cartoner – boundless optional configurations of the packaging system cover all product requirements.

Efficient

Optimum format utilization on account of product and blister rotation, which leads to minimum waste and maximum machine output.

Catalogs

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Sealing packaging machine

- Blister packaging machine

- Compact packaging machine

- Inspection system for the pharmaceutical industry

- Medicine packaging system

- Film packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Automatic cartoning machine

- Intermittent packaging machine

- High-performance packaging machine

- Capsule packaging machine

- Solids packaging machine

- Floor-standing cartoning machine

- In-line packaging machine

- Rotary packaging machine

- High-speed packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.