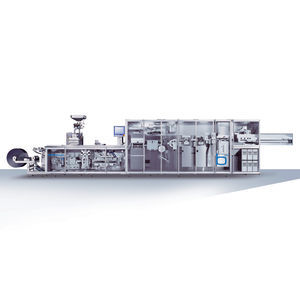

Automatic packaging machine BLU 200floor-standingcompactfor ampoules

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Configuration

- floor-standing, compact

- Container type

- for ampoules, for vials, for cartridges, blister

- Other characteristics

- modular

- Options

- with cartoner module

- Production capacity

200 p/min

Description

Blister machine BLU 200 is ideal for the packaging of small and medium-sized batches of parenteral products. The modular concept of the compact blister machine allows maximum packaging flexibility. The option of various feeding systems and efficient use of the entire width of the web lead to optimum machine output. Furthermore, the highly reliable process of the Blister machine BLU 200 offers gentle product handling, easy cleaning, and fast format changeovers, as well as user-friendly operation. All these factors contribute to the particularly high economic efficiency of the BLU 200.

Gentle product handling and top performance

A packaging process that handles parenteral products with utmost care pays off because every instance of damage leads to extensive cleaning, extra work, and longer downtimes. Gentle handling during the entire packaging process of the BLU 200 protects the glass products against breakage. The low drop height during blister removal is one feature in this context.

The BLU 200 is complemented by the Cartoner C 200.

Flexible

The modular design of the BLU 200 also enables the flexible packaging of smaller batches

Gentle

Careful handling as well as the GMP-compliant machine design avoid damage to the parenteral products

Reliable

Precision blister production and handling, state-of-the-art technology in the working stations, as well as the machine control system ensure top, reproducible results

Straightforward

Intuitive operation of the blister packaging machine and easy, guided format part changeovers using the SmartControl operating system; ideal access to the working stations

Catalogs

No catalogs are available for this product.

See all of Uhlmann‘s catalogsRelated Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Sealing packaging machine

- Blister packaging machine

- Compact packaging machine

- Inspection system for the pharmaceutical industry

- Medicine packaging system

- Film packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- High-performance packaging machine

- Intermittent packaging machine

- Solids packaging machine

- Automatic cartoning machine

- Capsule packaging machine

- Floor-standing cartoning machine

- High-speed packaging machine

- Rotary packaging machine

- In-line packaging machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.