- Secondary care

- Ophthalmology

- Optical lens edger

- US Ophthalmic

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

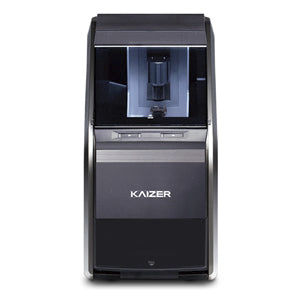

Optical lens edger HPE-910automatic

Add to favorites

Compare this product

Characteristics

- Type of system

- optical lens edger

- Options

- automatic

Description

The Huvitz HPE-910 edger offers advanced features designed to enhance efficiency and precision in lens processing. It boasts a built-in drill with exceptional durability, significantly reducing processing time by over 50%. The step bevel feature ensures perfect fitting with seven types and five edge styles, catering to diverse preferences. Equipped with a more powerful wheel motor and flexible adaptive chuck, this edger can effortlessly handle high-curve and various coating lenses. It excels in processing complex tasks, including variable asymmetric adjustments for height, such as Semi-U, Asymmetric, Partial Grooving/Beveling, Hybrid Grooving, and Dual Grooving. Additionally, its concave shape grooving and improved retouch capabilities further enhance its performance and versatility.

The configuration of the All Plastic diamond wheels allows for beveling of all materials, including CR39, polycarbonate, Trivex, and Hi-index. Additionally, a special configuration for glass can be requested. The high polishing function ensures high-quality finishes. With its multidirectional articulated terminal adaptable to the lens surface and its special program for hydrophobic lenses, the equipment ensures a perfect grip, preventing slips and improving accuracy in the beveling process.

The HPE-910 offers 35 types of finishing and positioning combinations to achieve a perfect fit between the frame and the lens.

The manual finishing position editor allows you to easily select the most suitable position for your frame in manual mode. For conventional frames and lenses, it is convenient to process them using the automatic position mode.

VIDEO

Catalogs

No catalogs are available for this product.

See all of US Ophthalmic‘s catalogsRelated Searches

- Ultrasound system

- Diode laser

- B/W ultrasound system

- Surgical table

- Universal surgical table

- Tabletop laser

- Examination chair

- Portable ultrasound system

- Specialized examination chair

- Adjustable height operating table

- Tilting surgery table

- Height-adjustable examination chair

- Electric surgical table

- Nd:YAG laser

- Electric examination chair

- Examination chair with legrest

- Surgery table with legrest

- Millisecond laser

- 3 sections examination chair

- Fixed ophthalmic examination

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.